Wheel Hub Deburring

JOB NO. 335

WHEEL HUB DEBURRING

APPLICATION

A manufacturer of large equipment needed a deburring solution at four separate surfaces of a machined hub. This wheel hub deburring work needed to be done on the outside and inside diameters of the hub within a short cycle time, meaning all ops had to occur simultaneously. A custom work holding fixture was required for this. The customer needed the ability to load by hand with provisions for eventual robot loading. Specific paint and safety requirements, including a free-standing electrical cabinet with high and low voltage separated, were also present. Customer optioned for a dust collection system.

SOLUTION

Processing

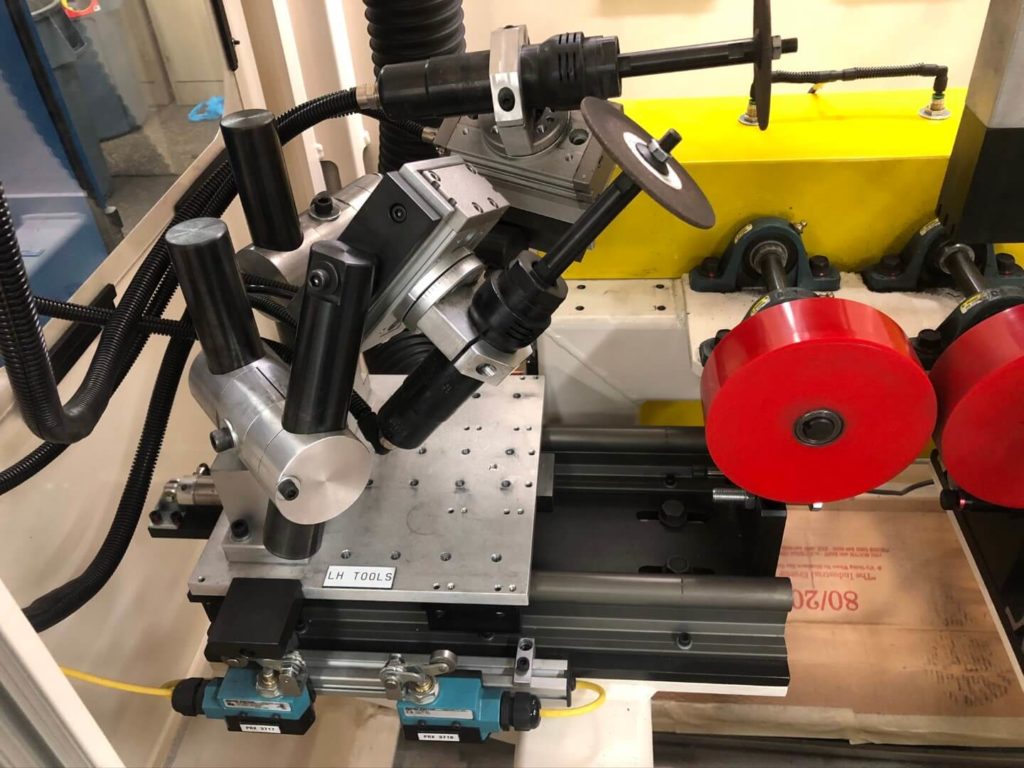

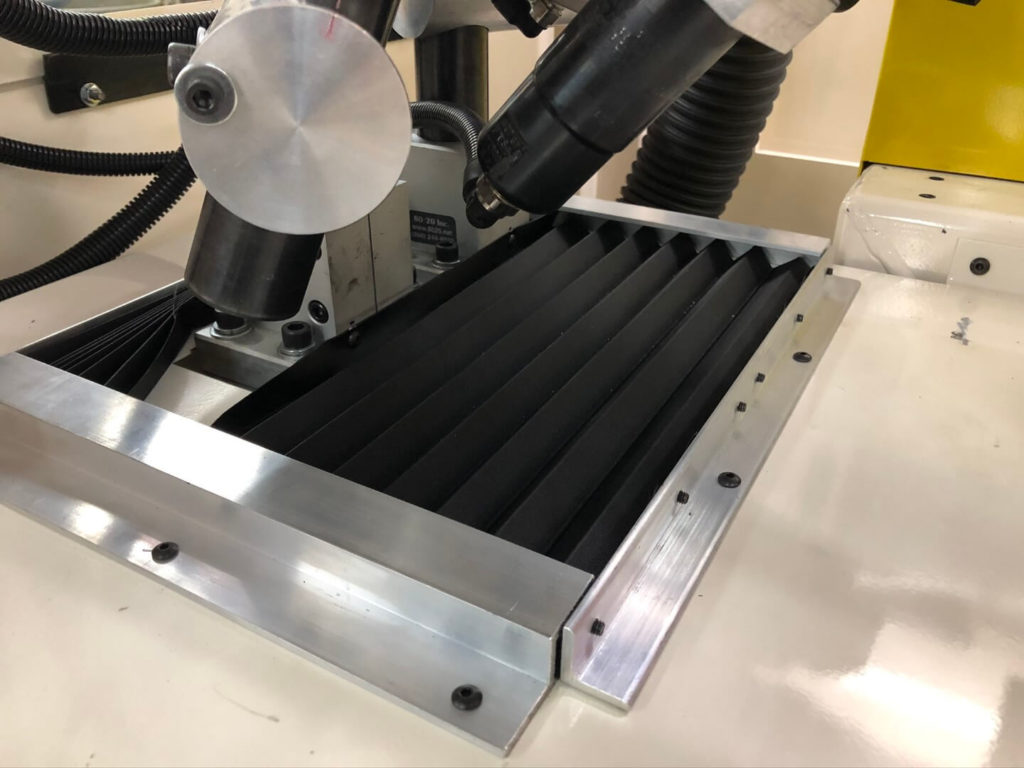

- In order to treat all four work surfaces in tandem, a drive roller/hold-down system is used. Two heavy duty rubber rollers are belt driven by a single motor and an industrial acetal hold-down block is pneumatically held to the hub, keeping it in place. Hold-down pressure is adjusted via a precision regulator.

- The inside diameter of the hub is treated by 3.5” nylon abrasive brush and a 3” steel wire knot wheel, both driven by air motors. Air motor speed varies depending on the media used.

- The outside diameter is chamfered by a pair of 3”-4” grinding wheels. These wheels are driven by 20,000rpm air motors. Precision regulators are used to control lift and cut pressures to all four cutting heads.

- All four cutting heads are mounted to adjustable arm assemblies. CDMC offers a wide range of arm options.

- In order for proper clearance to exist for an eventual robot load, grinder arm assemblies are placed on linear slides consisting of a set of rails/bearings and an air cylinder. Between load cycles, shuttle will retract all four arm assemblies. Aluminum extruded rails and bearings are optioned here to combat debris/early wear.

Safety/On Site Requirements

- This machine has paint spec’s for electrical and pneumatic components. CDMC is willing to fulfill paint spec’s for a cost.

- Electronic locking systems are mounted to manual doors for the highest level of safety. These switches disallow manual doors from being opened during operation and if bypassed, will send the machine into a fault state.

- Machine base is adapted for duct work and a custom pedestal stands near the unit, per customer request. Dust collection unit is from an outside manufacturer.

- Cabinets are mounted to a custom frame assembly in an attempt to condense the machine cell’s footprint.

Results