Differential Gear Deburring

Case B

JOBS NO. 333 & 294

HEAVY EQUIPMENT POWER TRAIN DEBURRING

APPLICATION

A manufacturer of heavy equipment components needed gear deburring to remove a very heavy burr caused by turning a finished gear face. Due to the amount of force required to remove this burr, the base and working components had to be very robust. The customer also had very specific paint and safety requirements, including a free-standing electrical cabinet with high and low voltage separated. Customer also optioned for a dust collection system.

SOLUTION

Machine Base

- A tall base made from ½” steel is used. The added height allows for vertical travel/adjustment of cutting head positions.

- Open port in machine roof allows for integration of duct work.

- Base interior has strong support system to accommodate robust components.

Processing

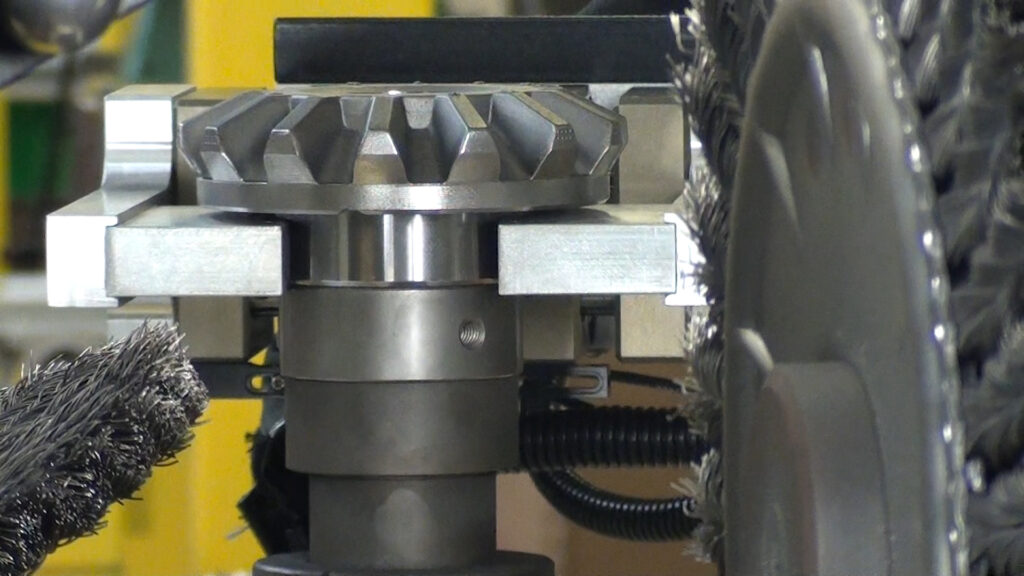

- Work is placed on a collet and taper assembly. The taper is hardened and machined to match/protect the profile of the clean gear face. The customer requires this surface to be unharmed by the aggressive brushing.

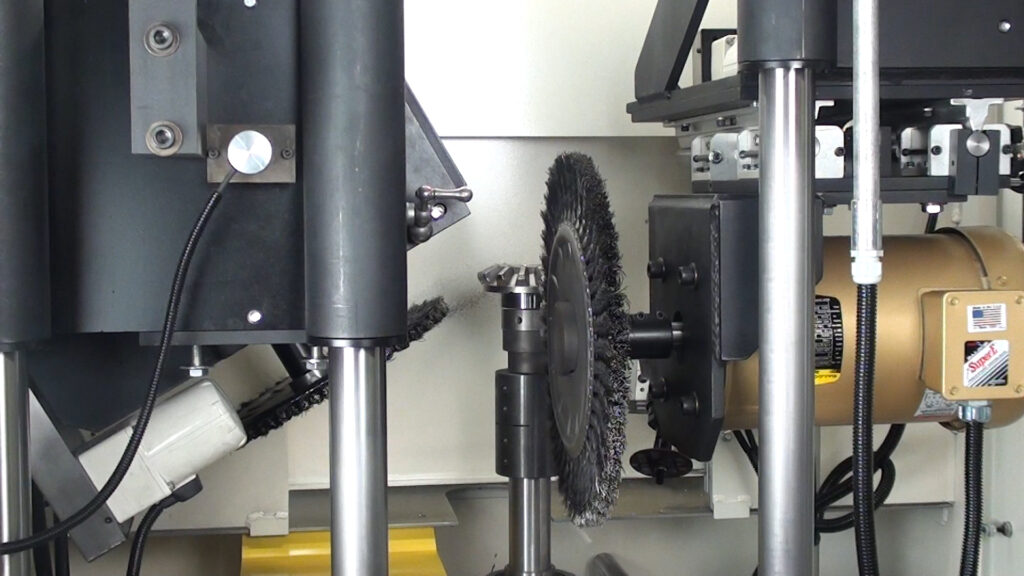

- Work is gripped on the ID by a collet assembly and hit hard by a pair of 15” steel wire knot wheels. One wheel works perpendicularly to remove the burr from center while the other works from an adjustable angle. We offer multiple options (assisted and manual) for adjustment of this angle.

- Each brush is directly driven by a large D.C. motor mounted to a heavy rail system. If the customer requires changeover to deal with different work heights, adjustments can be made along these rails.

- Auto Amp Compensation is utilized to achieve consistent results. Brush and part drive speeds can be adjusted via the HMI screen.

Safety/On Site Requirements

- This machine has paint spec’s for electrical and pneumatic components. CDMC is willing to fulfill paint spec’s for a cost.

- Electronic locking systems are mounted to manual doors for the highest level of safety. These switches disallow manual doors from being opened during operation and if bypassed, will send the machine into a fault state.

- Machine base is adapted for duct work and a custom pedestal stands near the unit, per customer request. Dust collection unit is from an outside manufacturer.

- Cabinets are mounted to a custom frame assembly in an attempt to condense the machine cell’s footprint.