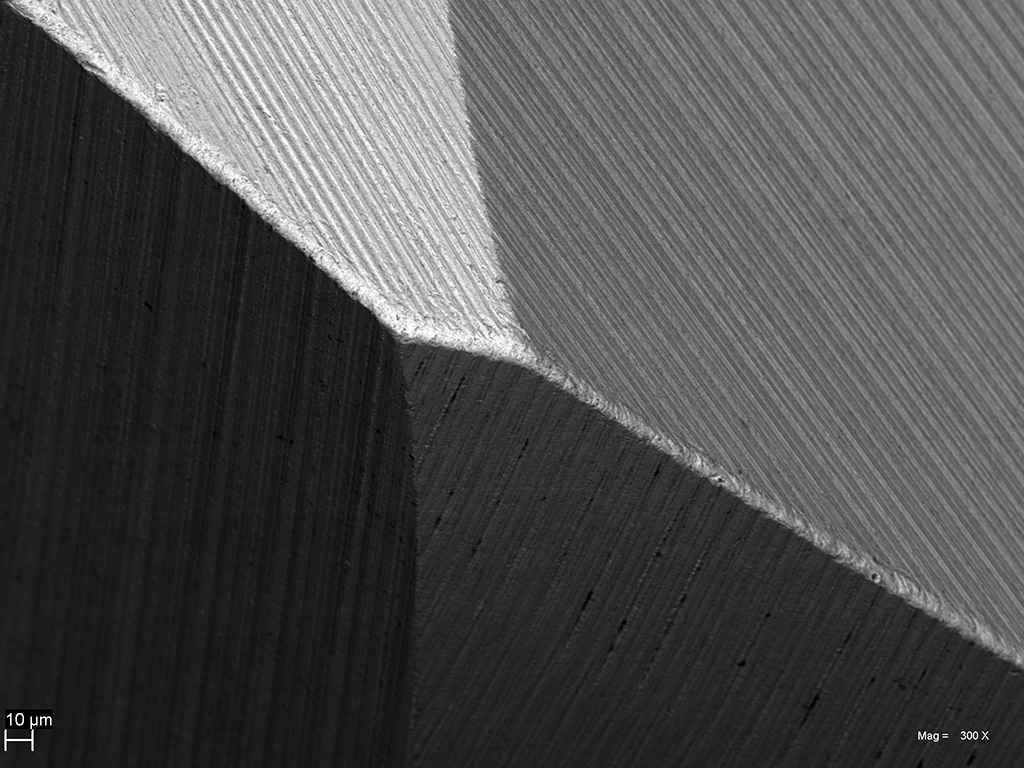

Precision Cutting Tool Edge Preparation

JOBS NO. 275 & 323

ROBOTIC AUTO LOADING

Application

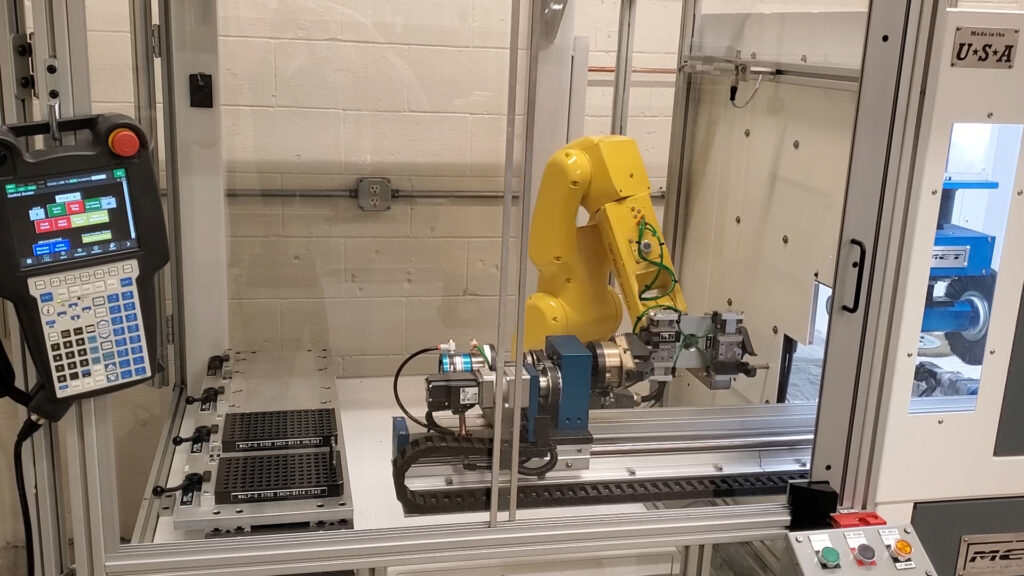

Numerous tool manufacturers requested the ability to auto load large pallets of tools into CDMC/MET tool prep machines for the purpose of precision cutting tool edge preparation.

Solution

Machine Base

- A simple base design with a steel tube frame, and 1” steel plate roof is used. This base has a low center of gravity, can support the weight of a robot loader and is easily transported via pallet jack.

- The base is designed to match the profile of the machine to be loaded.

- Aluminum extrusion and polycarbonate safety glass is used to guard the work area.

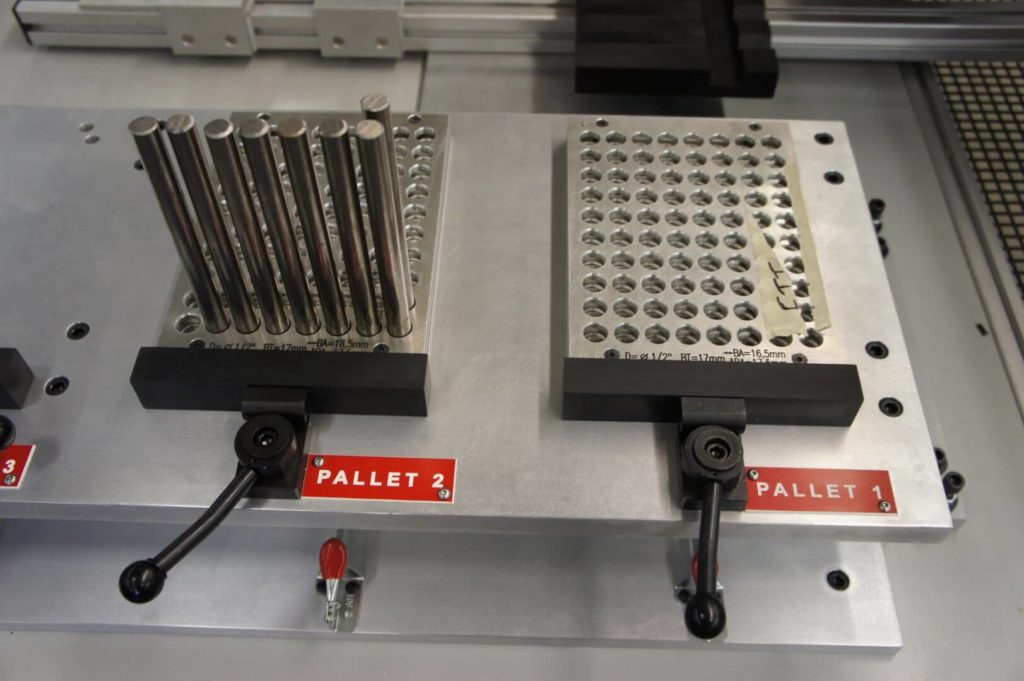

Processing

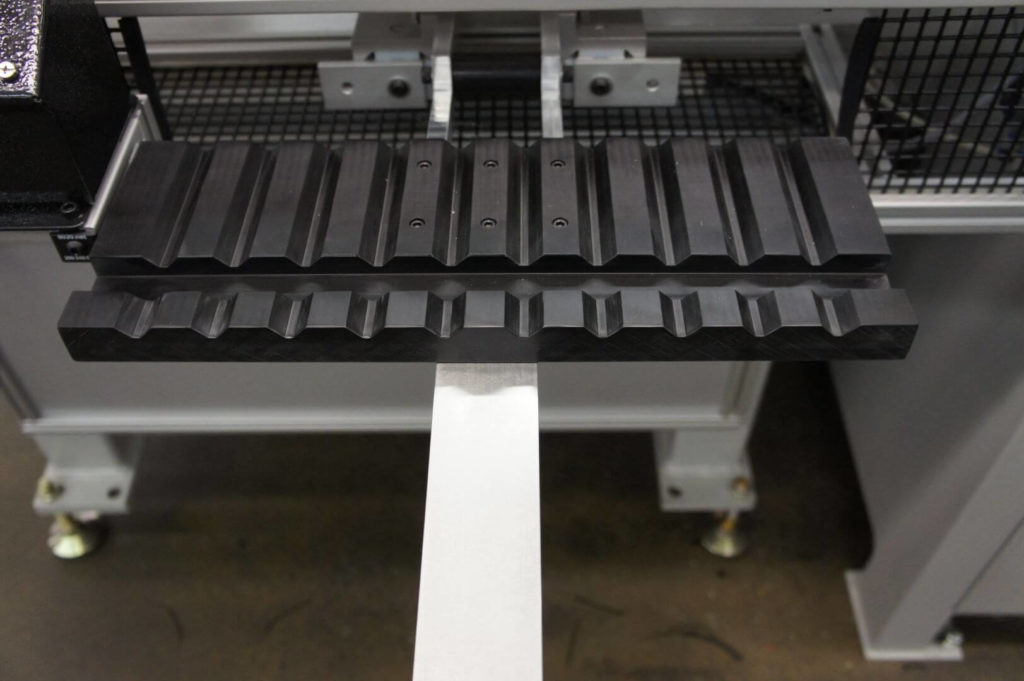

- Tool trays are loaded by an operator onto a ¾” aluminum clamping station. Four tool trays can be loaded at a time.

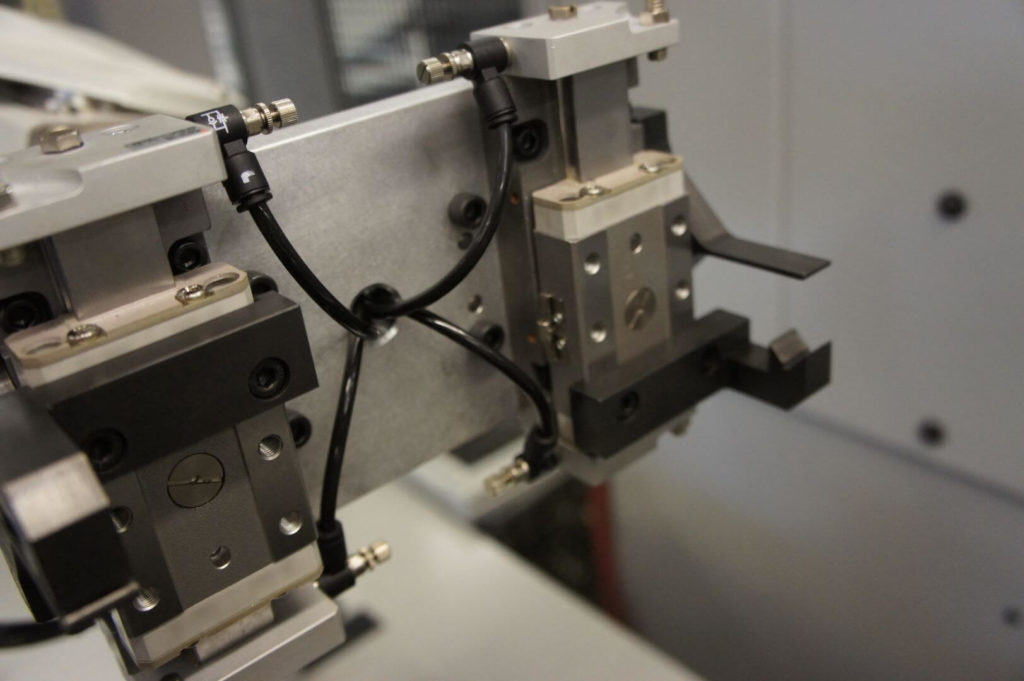

- Once a work cycle has been initiated, the robot travels a pair of gripper-equipped pneumatic linear slides into position above the tool to be loaded. Each pallet/tool size can be selected via the main machine’s HMI.

- The robot will repeat this process until all tools have been treated.

- Acetal resin inspection tables are used in the event of an operator wanting to check part quality. With the option selected on the main HMI screen, the robot will place a finished tool in the tray. An aluminum linear rail assembly allows the tray to be safely removed so that inspections can be performed while the machine is active.

Safety Implementations

- All manual doors are fitted with electronic safety interlocks. If a manual door is opened mid-cycle, the machine will stop/enter a fault state immediately.