Boehm Vitamix

JOB NO. 244

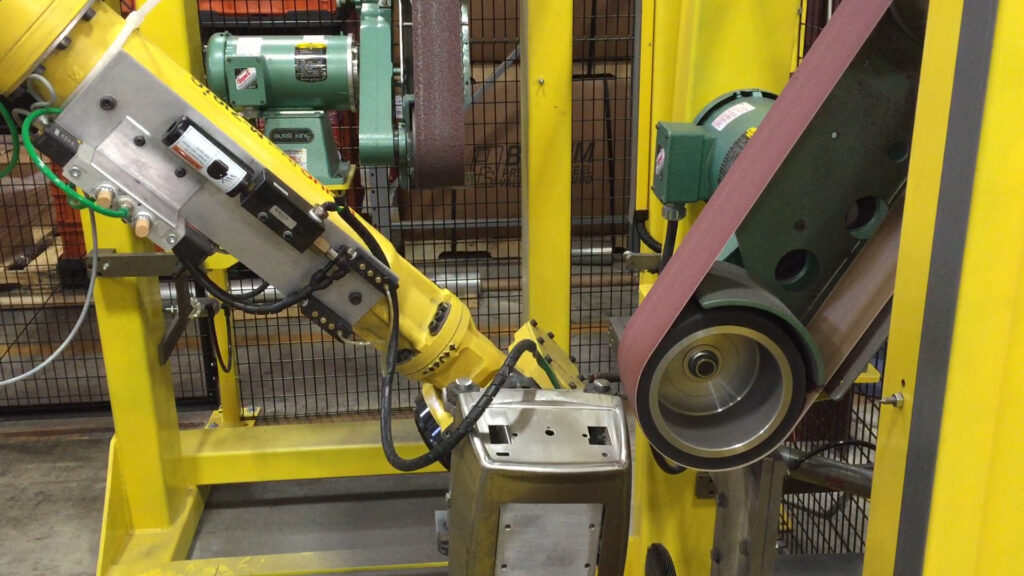

STAINLESS STEEL BLENDER BODY FINISHING

Application

A manufacturer of kitchen appliances required a way to efficiently and uniformly polish stainless steel blender body covers prior to final clear coat. Once a robotic deburring process had been agreed upon, a work cell had to be put in place with the necessary safety implementations.

Solution

Machine Base

- A 1” steel pedestal is placed at the center of the work cell for the robot. It is imperative that this pedestal has clearance for concrete anchors manufactured in.

- A second pedestal is placed in the incoming parts area for the incoming shuttle. This table consists of ½” steel plate supported by steel tubing.

- A number of riser assemblies that will house cutting equipment are placed around the work area, within the robot’s reach.

- A pedestal is required for the robot controller unit as well. Its construction is similar to that of the incoming parts station.

Processing

- Parts are placed by the operator onto custom acetal resin nests mounted to a ¾” carriage plate. The carriage plate is shuttled to/from work/load positions via linear rail system and air cylinder.

- The robot uses a vacuum cup system mounted to its arm end to reach into the presented part and lift it from the shuttle.

- Parts are brought to one of several work stations for processing. Cut actions similar to what would be performed by a human are done by the robot. These actions are taught by one of CDMC’s FANUC robot programmers.

- A work station consisting of a purchased Burr King belt sanding unit on a pivot uses varying grits of sandpaper to create a consistent matte finish. Belt sanders are held in a work position by pneumatic cylinders acting as a spring cushion. Digital precision regulators are used to monitor/adjust air pressure to these cylinders. Once the optimal pressure has been found, parameters can be kept/set to achieve consistent results from cycle to cycle.

- Work pieces are then brought to a directly driven abrasive flap wheel in order to treat corners and areas not reachable for the belt sanding stations.

- To create the final finish, work pieces are passed along a pair of directly driven buffing wheels.

- Auto Amp Compensation readings are used to determine buffing pressure via robot offsets.

Safety Implementations

- Industrial fencing is purchased and installed by CDMC. Any manual door used to enter the work cell is outfitted with an electronic interlock. If door interlocks are broken, the machine cycle will stop and enter a fault state.

Results