Camshaft Deburring

JOB NO. 139

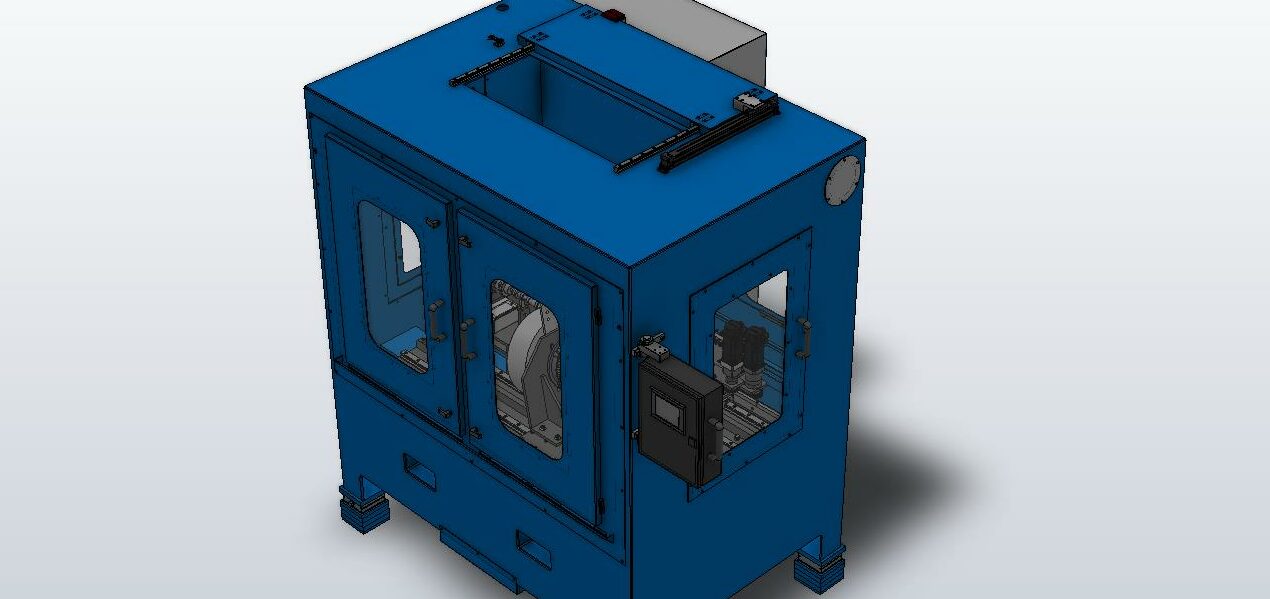

CAMSHAFT DEBURRING

APPLICATION

A manufacturer of heavy equipment needed a brushing machine for deburring camshaft lobes and undercuts. They also required a mobile work area for easy load/unload. Advanced safety implementations were also required.

SOLUTION

Machine Base

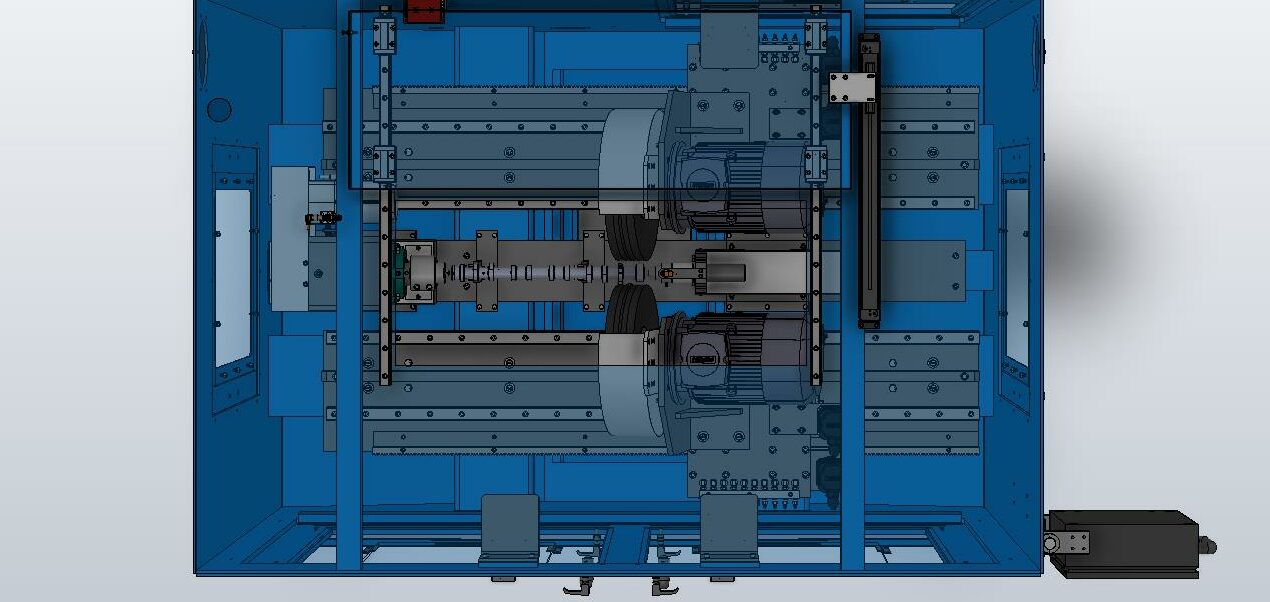

- A long base is required to accommodate a large range of camshaft lengths.

- The lower machine base is made deeper to accommodate a shuttling part drive assembly.

Processing

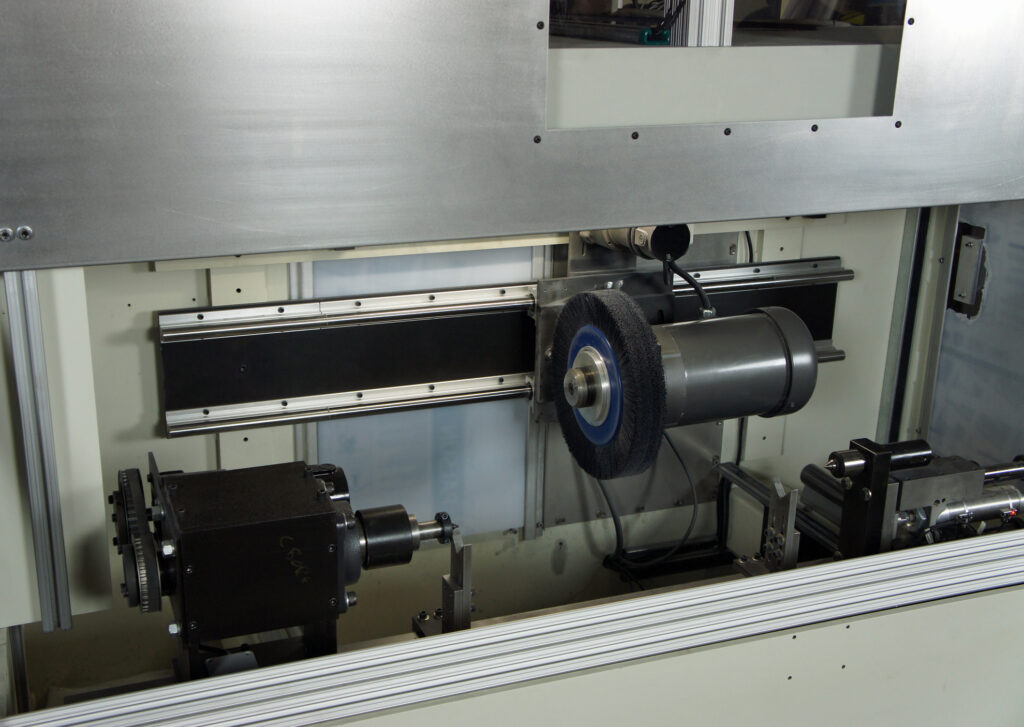

- Machine functions much like a lathe, with a stationary head stock and adjustable tail stock. Once loaded onto a set of vee rests, the operator can clear the work area and initiate a work cycle safely.

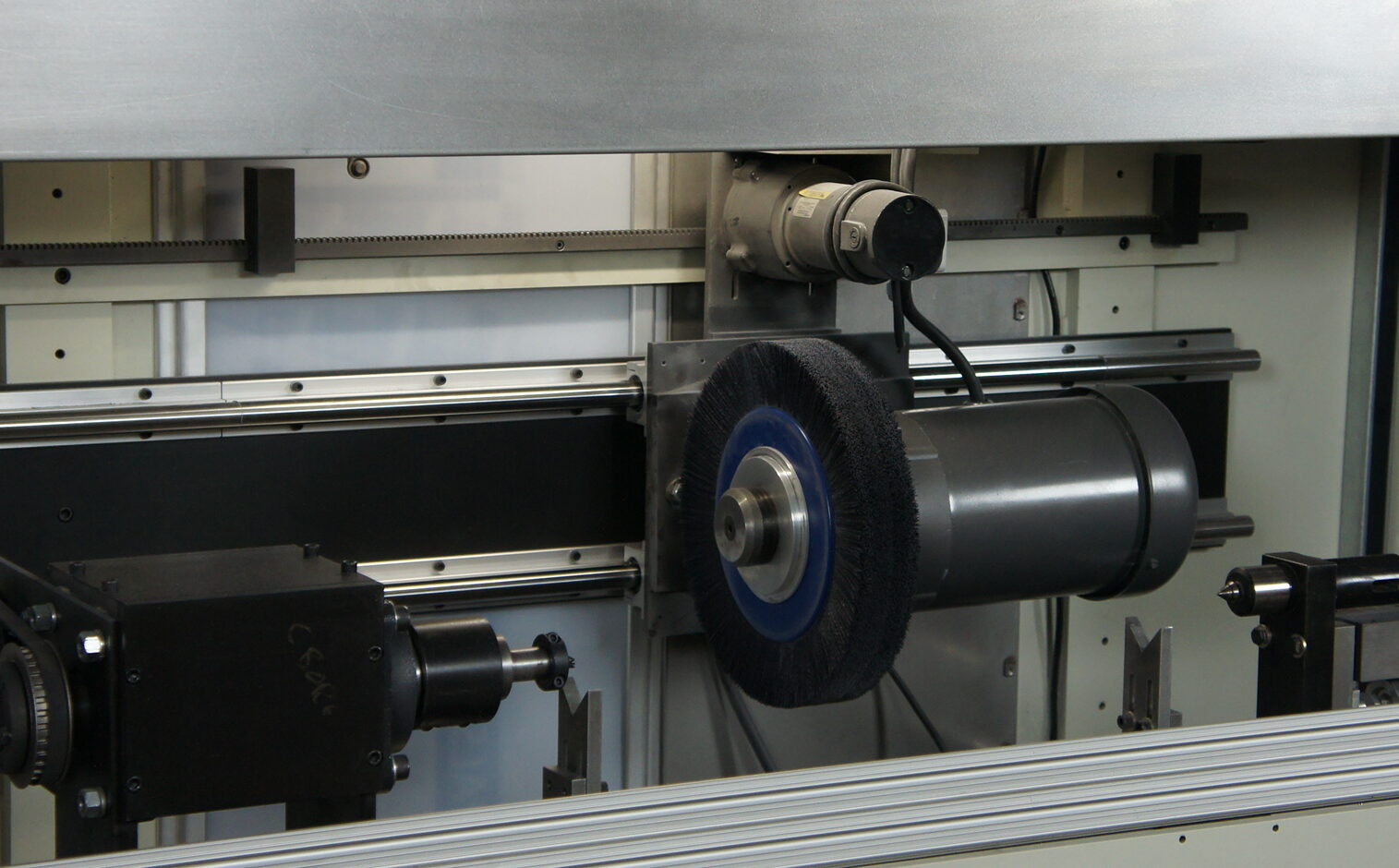

- Parts are brushed with a 14”-15” nylon abrasive radial brush directly driven by a large D.C. motor. The brush motor is installed to a pivoting plate assembly to allow for contact angle changes. Silicon carbide media is also available.

- A rack and pinion is used to transport the brush pivot assembly to each end of the work piece. Brush speed and travel are adjustable within the work program via the HMI screen.

- In order to utilize Auto Amp Compensation, an intelligent linear actuator is used beneath the part shuttle table to adjust brush contact pressure, pulling from/pushing toward the media as necessary. This ensures consistent performance throughout the entire length of the work piece.

- Brush time and travel can be adjusted via the HMI screen as well.

Safety Implementations

- Light curtains are used to keep the load/work areas clear and safe when a cycle has been initiated. If breached during a cycle, the machine will immediately stop and enter a fault state.

- A single-cylinder auto door allows the work area to be clear and safe upon cycle initiation.

- All machine doors are equipped with safety interlocks or are tool removeable.