Descaling and Finishing

JOB NO. 107

Mining Torque Rod Finishing

Application

A manufacturer of large mining equipment required a solution for descaling and finishing a family of axle shafts. Customer optioned for a wet application (coolant to cool parts/media and help with cut) and the inclusion of an external work station for wash down/extra operations. These components act as a mechanical “fuse” to protect more expensive components.

Solution

Machine Base

- A large, heavy-duty base is needed to support the robust roller system and cutting heads needed to process a part of this size.

- Base is extra wide to accommodate a large range of part lengths.

- Water-tight fabrication is absolutely necessary due to large amounts of coolant that will flow to the cutting heads and work surface.

- Base includes an external, open compartment to be used for an external part drive assembly. This allows for extra ops to be done post-descale.

Processing

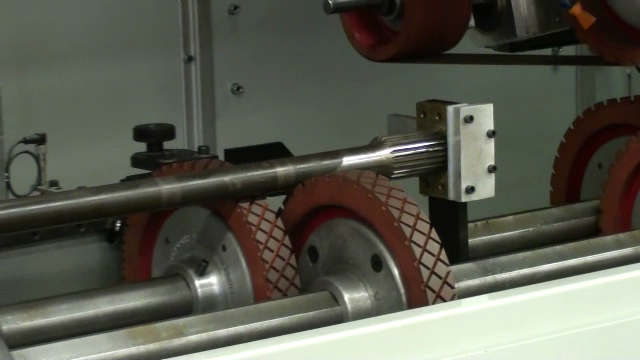

- A pair of 2” shafts running parallel to each other are equipped with 8”-12” diameter rubber roller wheels. The shafts are driven in tandem by an offset chain drive assembly with variable speed. Drive wheels have a heavy rubber outside diameter with recessed tracks to allow coolant/debris to escape the work area. The work is held in place by adjustable end-stops.

- A rack and pinion is used to transport a buffing head and sanding head along the length of the work piece. In this instance, a Burr King unit was purchased and fitted to the machine, acting as our sanding station. These cutting heads travel along a linear rail assembly. Cutting heads utilize Auto Amp Compensation for consistent cycle results.

- As cutting heads engage the work piece, they are fed a stream of coolant at their contact points.