Cat

JOBS NO. 128/150

LARGE GEAR DEBURRING

APPLICATION

Various heavy equipment manufacturers require affordable solutions for deburring/chamfering large gears for tractors and construction equipment. These machines must be capable of being gantry loaded due to the weight of the workpiece. In almost all large gear deburring or chamfering applications, gear rotation must be monitored as to achieve a consistent chamfer and not overlap and cause mismatched cut dimensions.

SOLUTION

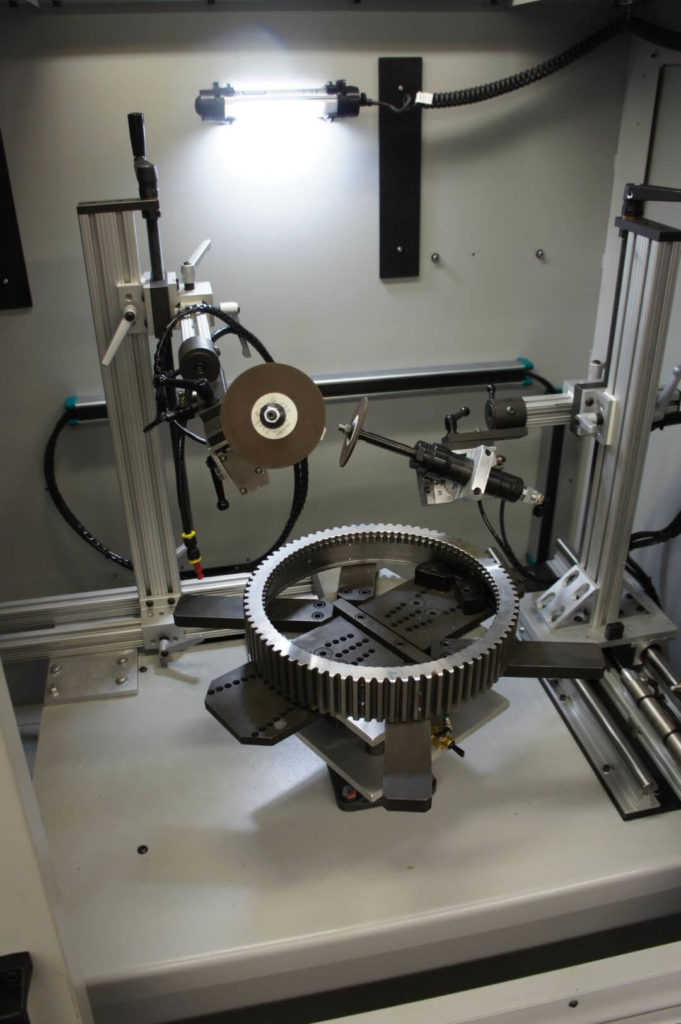

Machine Base

- A heavy duty, open base with ample face/roof openings is used to accommodate the mass of the work piece. A horizontal sliding door is used to safely enclose the work area while allowing easy loading. This door design is available in manual or automatic function.

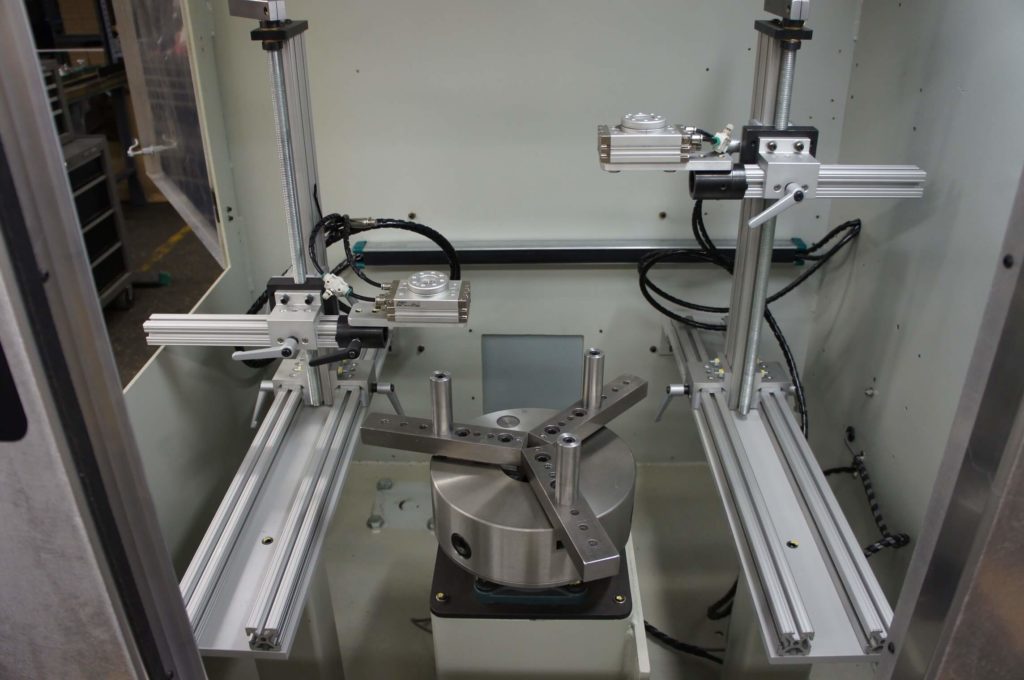

Work Holding

- Large gears are held in place by a custom chuck assembly. The assembly is robust, open and easily maintained. Clamp pins are pulled/pushed into place by a cylinder/pivot assembly directly underneath the top face of the chuck. Traditional manual chucks are also available with quick-change jaw tooling.

- Parts are driven by a belt/pulley system. By offsetting the drive motor, we created an easily serviceable part drive assembly and smaller machine footprint. Drive motor speed is variable via HMI inputs.

- In order to monitor rotational accuracy, a magnetic proximity switch is used below the work area. The sensor counts the teeth of a spur gear mounted directly to the part spindle and relays that information to the work program.

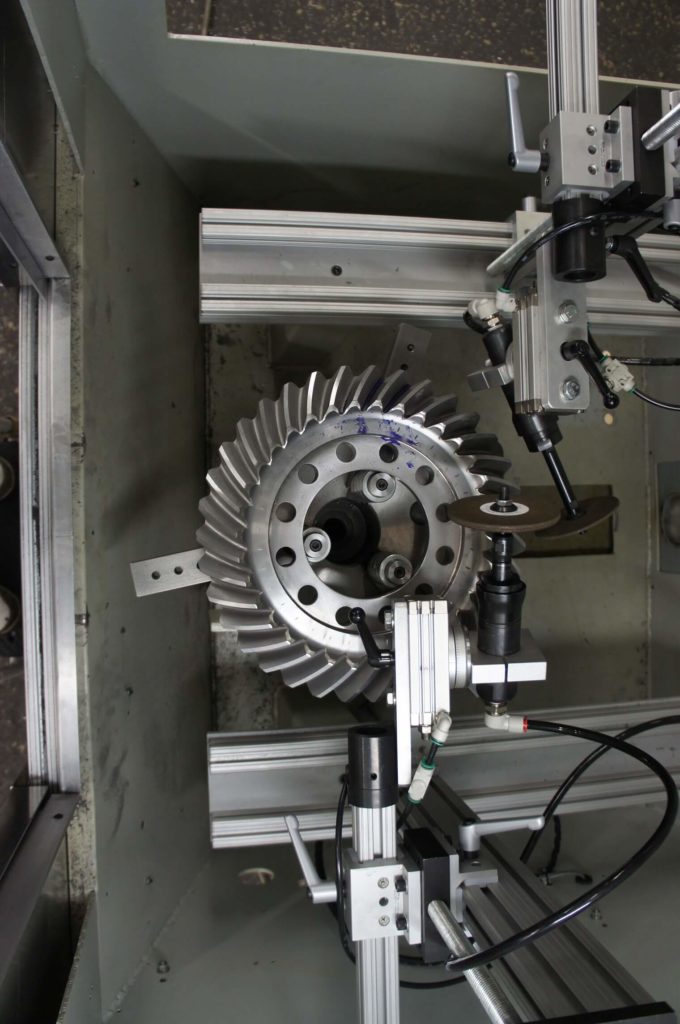

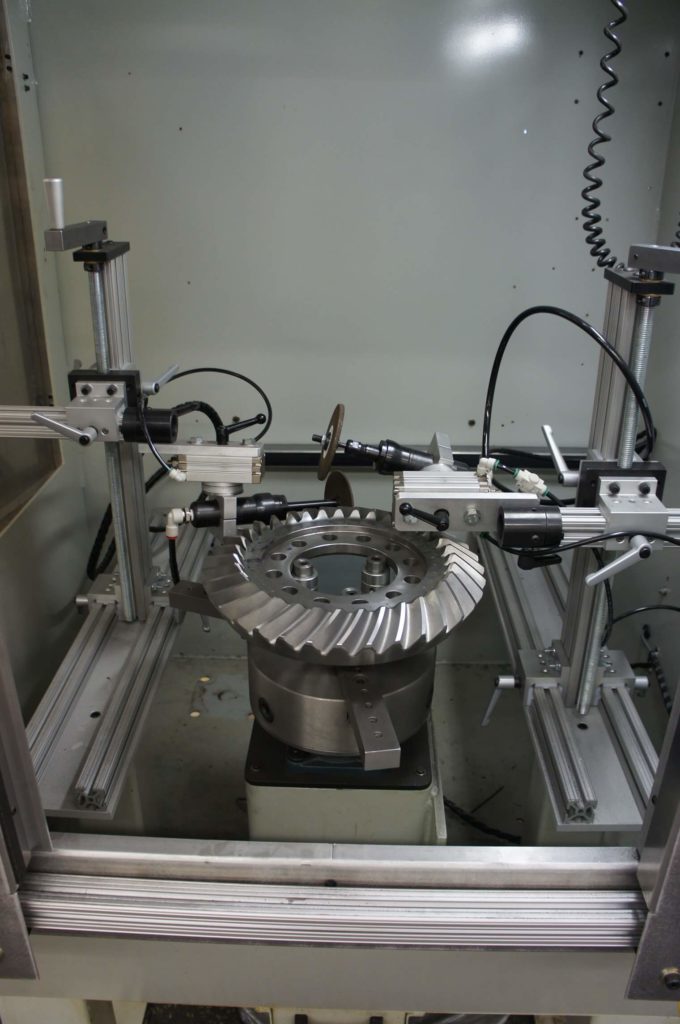

Processing

- Two high rpm air motors are used to drive a 4”-6” grinding wheel. Specific air motor speed is determined by the size/material of the cutting wheel used. The use of two cutters allows us to chamfer the top and bottom of a gear or acute/obtuse gear sections in tandem.

- Air motors are held near center by a rotary actuator. The rotary allows the cutting wheel to follow work piece profile freely.

- Precision regulators are used to control cut/lift air pressures at the rotary. Adjustments to cut/lift pressures change depth/width of chamfer. Once the proper dimension is achieved, cut/lift pressures can be saved and monitored to maintain machine performance from cycle to cycle.

- Cutting head assemblies are held in place by adjustable arms. CDMC offers a wide range of arms depending on customer preference and will also design custom arms.

Low End Machine

Mid Range Machine

Retro Fit Machine

Results