Near Net Forged Part Deburring

JOB NO. 108

LOW VOLUME NET FORGED PART DEBURRING

APPLICATION

A manufacturer of diff gears needed a low-cost deburring solution. This machine was to be hand loaded and treat one gear at a time.

SOLUTION

Machine Base

- A standard sheet metal model 1000 base is used. This base provides easy access, makes a small footprint and is easily transported via pallet jack.

Processing

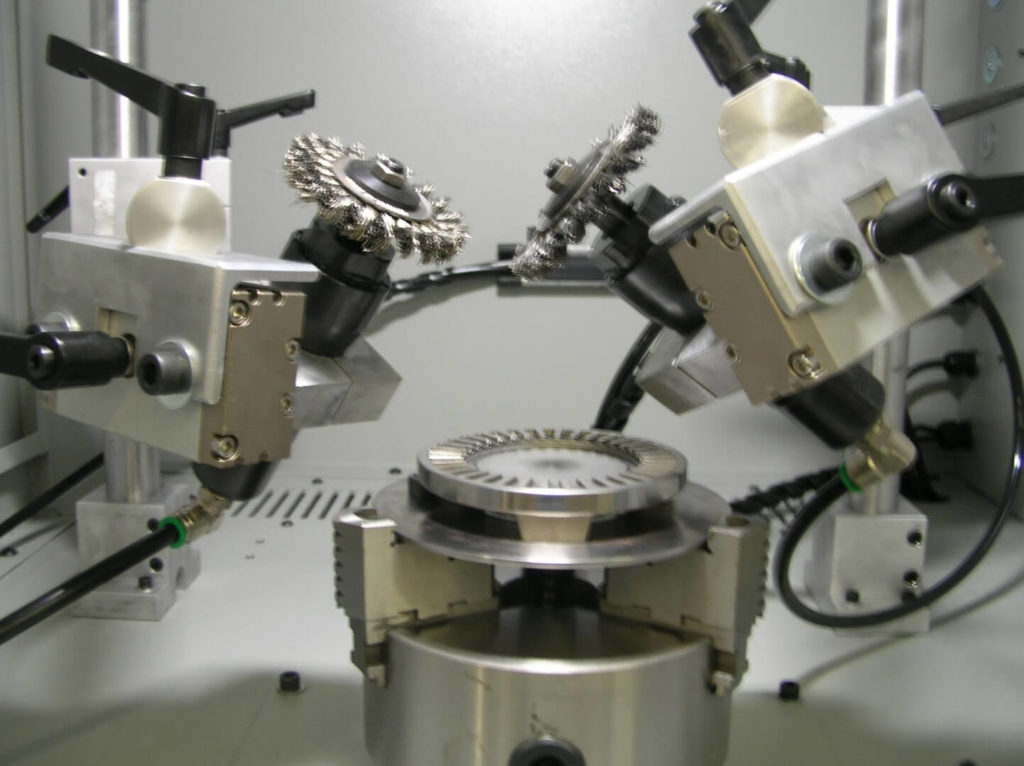

- Gears are placed onto a manual chuck and clamped by the operator. The chuck spindle is belt driven by an offset D/C motor.

- A pair of steel wire knot radial wheels driven by high rpm air motors are brought to their work position by pneumatic rotary actuators. Cut and lift pressures to these rotaries are precision regulated for consistency of cut.

- As the wire wheels engage, the part spindle is rotated at a speed/timeframe selected on the HMI screen.

Safety

- All manual doors are electronically interlocked. Breaking an interlock will stop a machine cycle.