Motorcycle Camshaft Deburring

JOB NO. 282

MOTORCYCLE CAMSHAFT DEBURRING

APPLICATION

A manufacturer of motorcycle camshafts needed an affordable, small-scale deburring solution.

SOLUTION

Machine Base

- A standard Model 1000 sheet metal machine base is used here, with removable panel-enclosed lower storage and a vertical polycarbonate glass auto door assembly.

Processing

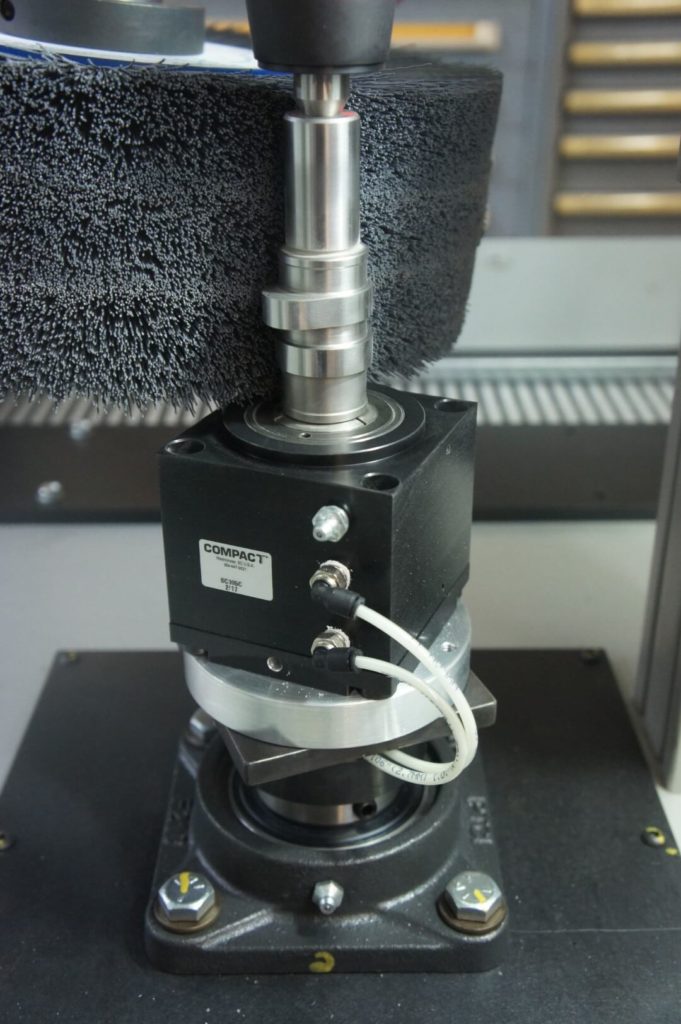

- Shafts are hand loaded into a purchased pneumatic collet system. This system is clamped and rotated by a pneumatic rotary actuator/offset D.C. belt drive.

- A live center tail stock assembly clamps the exposed shaft end via pneumatic linear slide. The tail stock is mounted to an aluminum extrusion slide/bearing and is easily height adjusted.

- A stack of directly driven 12” nylon abrasive radial brushes are brought in on a large pivot assembly to treat the shaft. Cut pivot is controlled by pneumatic cylinder and can be precision regulated for consistent performance. The brush motor assembly can be set to a cant to enable a slight cross cut.

Safety Implementations

- All door panels are electronically interlocked. Breaking an interlock will stop the machine cycle and cause a fault condition.

- This machine is equipped with a two hand start, meaning that both operator hands must be present at safety starts in order to initiate cycle start.