Chrysler

JOB NO. 520

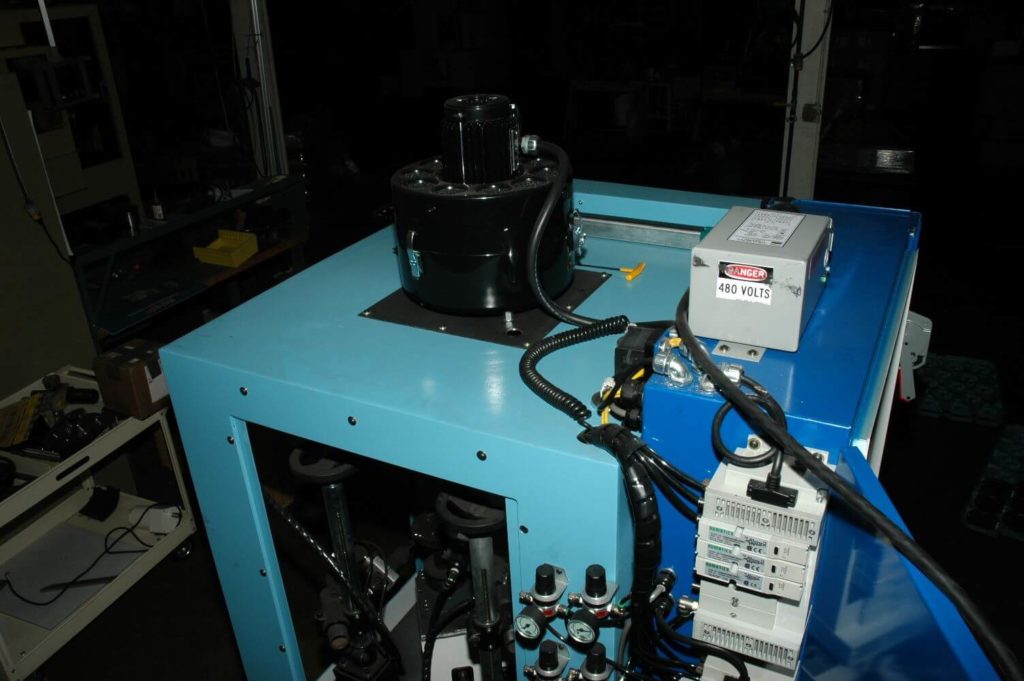

TRANSMISSION GEAR DEBURRING

Application

A ‘Big Three’ automotive manufacturer needed a small machine to handle operator loaded transmission gear deburring.

Solution

Processing

- Gears are hand loaded onto a part drive spindle and clamped with a collet. The part drive spindle is belt-driven by an offset D/C motor. Part rotational speed is adjustable via HMI screens.

- A 6” nylon abrasive radial brush and a pair of 2.5” grinding wheels are used to deburr the part. All cutting media is directly driven by high rpm air motors.

- The nylon brush is brought to cut/retract positions by a pneumatic linear slide assembly. The vertical height of this brush is tool adjustable.

- Pneumatic cylinders are used along with bearing blocks to create a rotary, allowing grinding wheels to follow the gear tooth profile smoothly. Cut and lift pressures to this device are precision regulated and can be optimized for repeatability of cut aggressiveness. Grinding heads are installed to adjustable arm assemblies. CDMC offers a wide range of tool arm options.

Safety/On Site Requirements

- A safety start switch is used in conjunction with a horizontal sliding door assembly guarded by light curtains. The auto door allows for operators to be clear of the work area upon cycle start and light curtains prevent any machine function with an operator/obstruction in the general work area.

- CDMC followed this customer’s custom paint requirement.