Powdered Metal Components

Case A

Application

A manufacturer of PM planetary carrier components needed large scale deburring solutions for two separate parts. These machines had to be robust and capable of processing hundreds of thousands of pieces within a short cycle time per piece. Wet and dry applications were both required along with any plumbing/dust collection, respectively. Any exterior part transfer must be safety guarded.

Solution

Machine Bases

- In order to process high quantities with multiple ops in a small footprint, medium sized rectangular bases are used. A clearance at the machines’ roofs allows for a 2” index shaft to move work spindles from op to op.

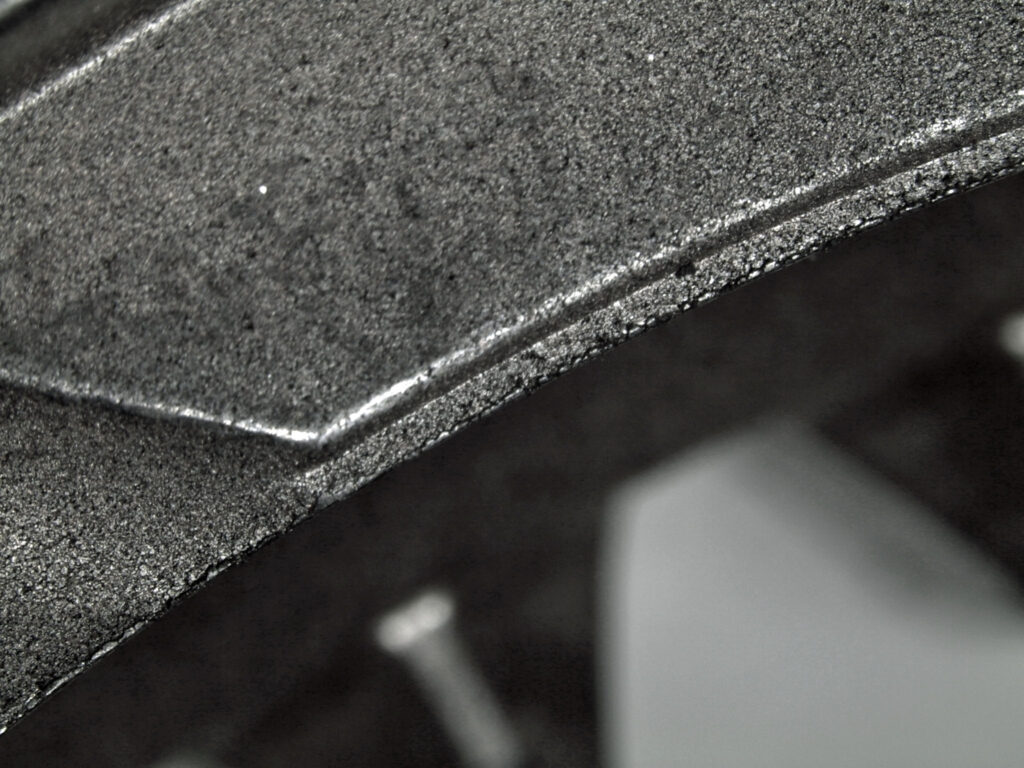

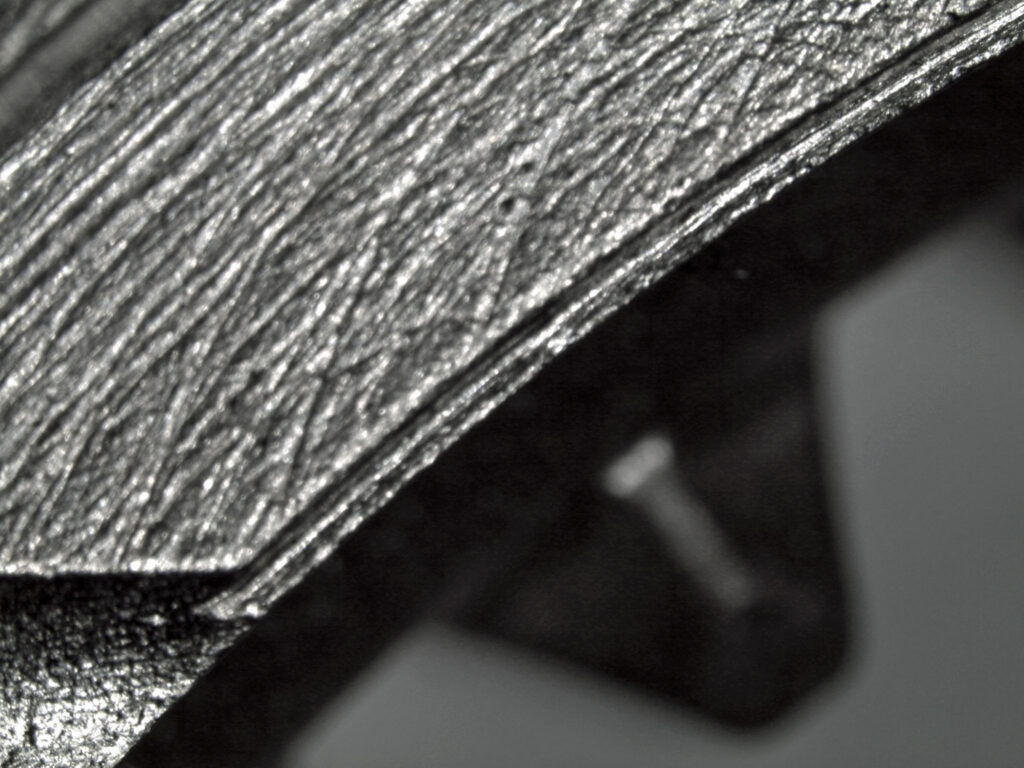

- 3/8”-1/2” steel plate walls must be used to support any heavier assemblies that will be under pressure/performing deburring ops.

- The wet application’s base must be welded water-tight while the dry application’s base does not have to be completely sealed.

Processing

- Work pieces are fed onto the incoming conveyor. After passing a series of pneumatic feed escapements, they arrive at a resin load nest held in place by a pneumatic rotary actuator. As they are held at “load”, a 2-axis pneumatic slide assembly brings a two-jaw gripper to its “clamp” position. Once the work has been clamped and lifted, the load nest retracts to allow for outgoing work to exit.

- Each part drive spindle is installed to a 1” aluminum dial plate driven by a four station CAMCO indexer. The CAMCO indexer provides excellent locational repeatability. Independent part drive assemblies are located on pivots at each work station, using high torque A/C motors to drive stationary gears. As each spindle is indexed in place, a corresponding gear will mesh with the independent part drive gear.

- Once loaded and clamped to the part spindle via collet/draw bar assembly, work pieces are indexed through a series of deburring ops done by nylon abrasive radial and end brushes. All brushes are directly driven by large frame D/C motors utilizing Auto Amp Compensation. Brush motor assemblies move to work/home positions via 2”-3” pneumatic cylinder/linear rail assemblies, with fine adjustments to cut feed/cut retract controlled by intelligent linear actuators.

- With all first machine deburring ops complete, the work is unloaded from the same position it was loaded to. The work exits the first machine to an external transfer station where a larger 2-axis pneumatic slide assembly picks/transfers it to the second machine for the final set of ops.

Safety/On Site Requirements

- A stand-alone DONALDSON TORIT dust collection unit is provided by CDMC along with a custom aluminum extrusion pedestal above the machine cell. All duct work is provided by CDMC.

- Due to the presence of an external transfer station, aluminum extrusion and mesh safety fencing is used along with any required safety interlocks to keep the area between each machine safe.

- Electric cabinets can come air conditioned at a customer’s request.

- Mobile HMI pendant assemblies allow monitoring of both machines from various locations