Automotive Gears – American Axel

Application

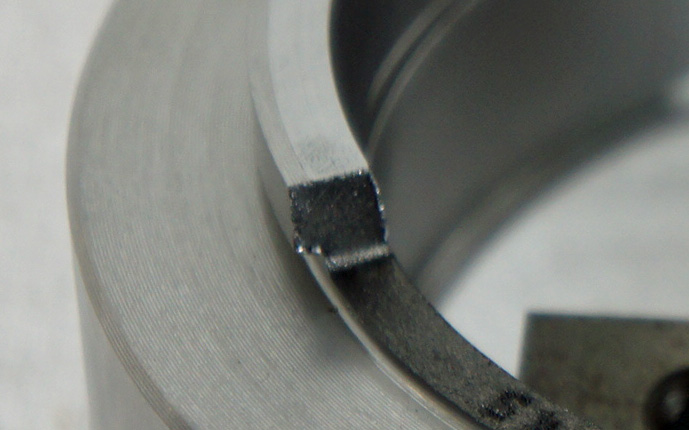

A manufacturer of automotive sprockets and gears required a deburring solution for extremely high quantity work pieces. The machine needed to be efficient and produce results within a short cycle time. Parts were to arrive via customer conveyor system and required an auto loading system. A coolant system was required to aid tool life along with an external parts washer post-deburr.

Solution

Machine Base

- In order to cycle/treat high quantities with various ops, a dial machine is used here. The machine base is a tall rectangle with a pivot shaft clearance at the roof’s center. As this is a wet operation, the base needs to be sealed water-tight.

Processing

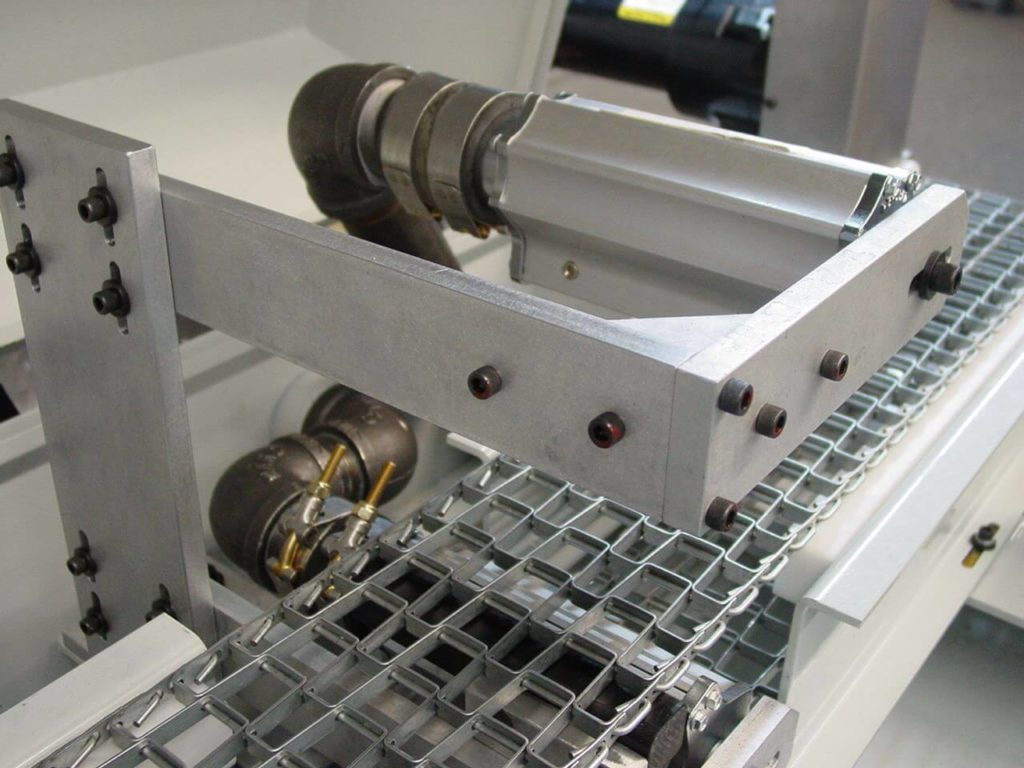

- Parts are loaded onto a small conveyor assembly where they proceed to a set of pneumatic feed escapements, and then to a rotary actuated load nest. A custom-tooled two-jaw gripper is lowered into place by a pneumatic linear actuator. Once clamped and lifted, a pneumatic rotary actuator flips gripper positions from conveyor to load spindle. Any finished part exiting via load spindle will be unloaded as the new part load occurs.

- Part drive spindles are installed to a ¾”-1” aluminum dial plate, allowing them to be indexed from station to station. A CAMCO indexer located atop the machine base is used and provides excellent locational accuracy.

- Once loaded onto one of three collet/base assemblies, the work piece is clamped via pneumatic draw bar and indexed to each work station, getting brushed by a pair of 6”-8” nylon abrasive end brushes. End brushes are directly driven by large frame D/C motors that utilize AAC and are horizontally adjustable. A linear rail and actuator assembly is used to feed/retract each brush.

- Coolant lines are piped to each work area and can be used to aid the cutting process or wash down critical components.

On Site Requirements

- A PRAB coolant pump/filtration system is provided by CDMC along with all piping/nozzles. Cleaning implementations such as bag filtration, magnetic separation and oil skimming are available upon request.

- CDMC is capable of providing independent washing machines in house or through WALSH MANUFACTURING.