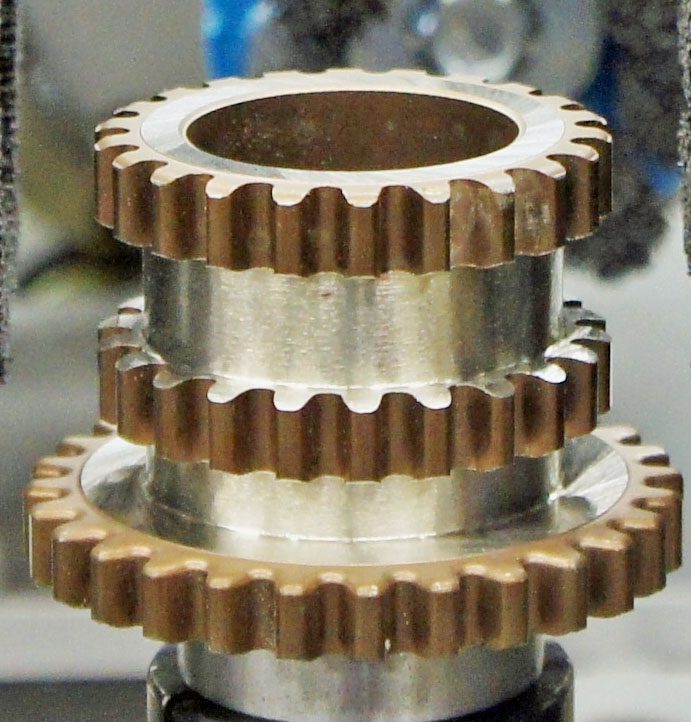

Abrasive Machined Sprockets

Application

A manufacturer of automotive sprockets needed a low-profile deburring machine to fit into a finished manufacturing cell. Due to the lack of a deburring solution in the already finished cell, this machine had to be exceptionally small while still including all necessary media to obtain the desired part quality. A custom design was required to allow the machine to be loaded by an existing robot.

Solution

Machine Base

- A low-profile base is used along with a custom auto door assembly specifically designed to work in the confines of an existing cell.

- Slotted clearances located in the machine’s roof allow for external slide assemblies, saving internal machine space.

- 3/8” steel plate is used for machine walls along with custom auto door panel in order to support heavy brush head and spindle assemblies

Processing

- With a cycle initiated, the machine’s steel plate auto door is pneumatically opened to present the part drive spindle located on the other side. In order to save space/cost and work with the existing robot, an A/C belt drive mounted on the auto door exterior drives a spindle assembly mounted directly to the door interior. When the door swings open via 2” round steel hinge, the part drive spindle is presented to the robot as well.

- Once loaded, the sprocket is clamped by a pneumatic draw bar and collet assembly. The auto door closes, bringing the sprocket directly to the work position.

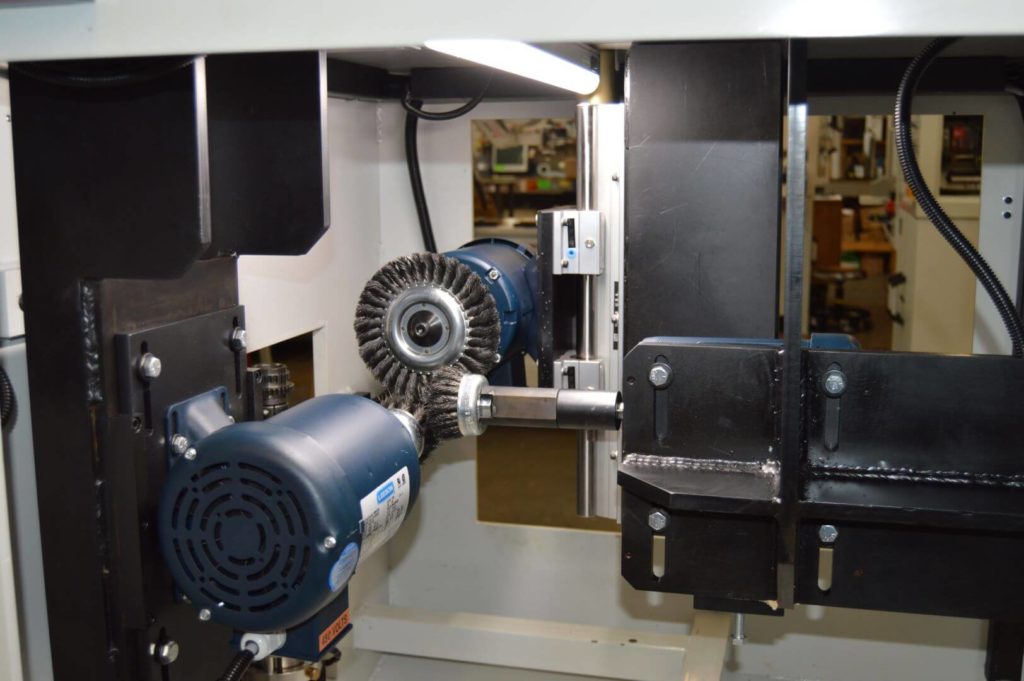

- Once “auto door to close” is confirmed by a magnetic proximity switch at the door hinge, a work cycle is initiated. Sprockets are treated by a pair of 3” twisted steel wire cup brushes and a 6”-8” steel knot wire radial brush. Each brush is directly driven by a LEESON D/C motor, utilizing Auto Amp Compensation.

- Brush assemblies are fed/retracted by linear rail and actuator assemblies. Horizontal rails are located on the machine roof while the vertical rails are located in the main work area.

Safety/On Site Requirements

- Custom sheet metal is placed along horizontal rail clearances to prevent debris from escaping the work area.

- All manual doors are electronically interlocked. Breaking an interlock will stop the machine from cycling and create a fault condition.