Cutting Tool Edge Preparation

JOB NO. 239

CYLINDRICAL CUTTING TOOL EDGE PREP

Application

A large automotive manufacturer required a means to more effectively and consistently polish/treat cutting tools to be used in their machining centers. Our goal was to provide an intelligent, capable machine within a limited footprint.

Solution

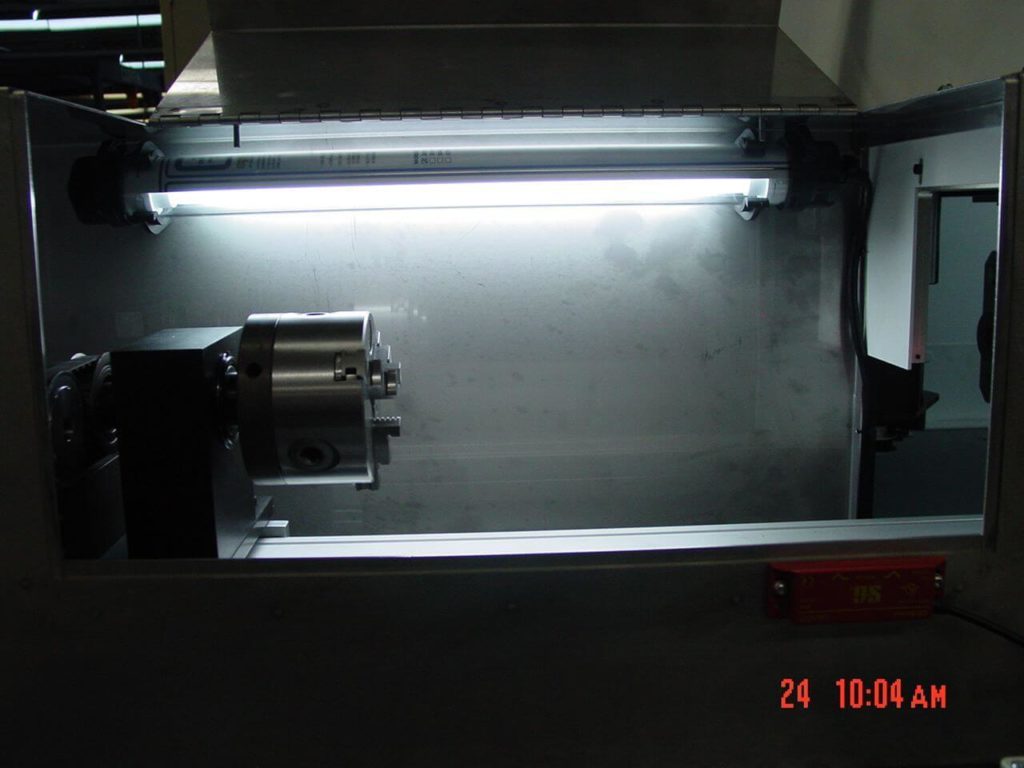

Machine Base

- Low cost sheet metal is used to create a simple rectangular enclosure with accessible openings. Keeping the weight down allows this machine to be relocated with a pallet jack. A top cabinet is used to house the work area while the lower cabinet can be used for storage or an optional dust collection system. The top cabinet is clearanced for a shuttle slide/loader assembly and the electrical panel is directly built in.

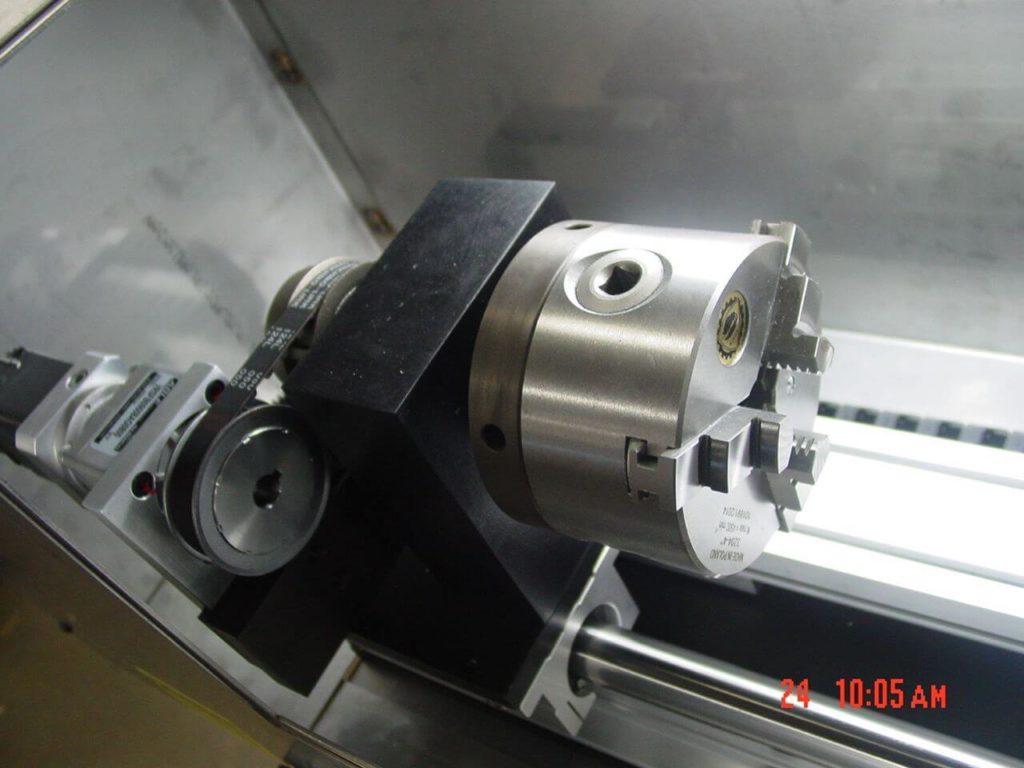

Processing

- A wide range of drills, end mills and reamers can be clamped by operators in the machine’s work holding (a manual bison chuck). We currently offer a base, direct drive spindle for shorter to average length tools as well as an offset thru-hole spindle for longer/intermediate sized tools. A pneumatic version is also offered for automatic clamping.

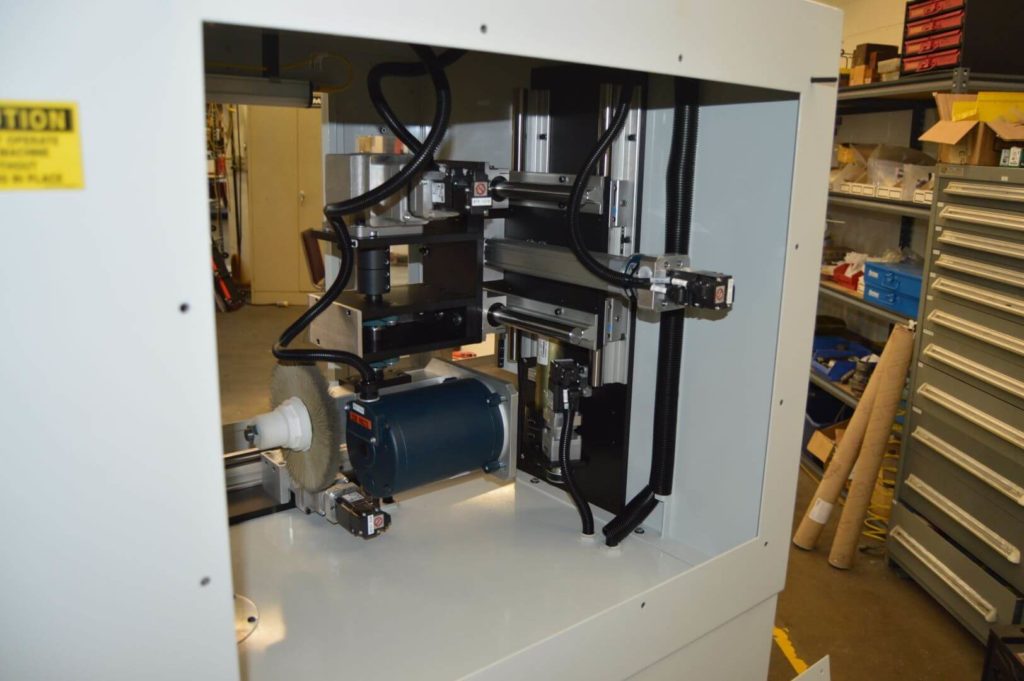

- The tool is shuttled into the work area via servo slide. Once detected by a laser, a diamond, nylon or silicon carbide abrasive radial brush is used to polish or radius the desired cutting edge.

- Abrasive brushes are belt-driven by a ¾” shaft and D.C. motor. Servo brush motors are also available.

- All linear, as well as brush pivot motions are controlled via servo. This ensures extremely accurate locational data can be used to write programs that maximize efficiency and achieve the desired edge break.

Dust Collection

- A dust collector is located beneath the work area in an easily accessed storage area. Flexible duct is routed from the collection unit to the work area and can be placed in multiple positions to maximize efficiency.

Safety Implementations

- The exterior loader is covered by an aluminum shroud/access door. Safety interlocks ensure that if the access door is open, the machine will not cycle. All other panels leading to the work area are either electronically interlocked or tool removable.