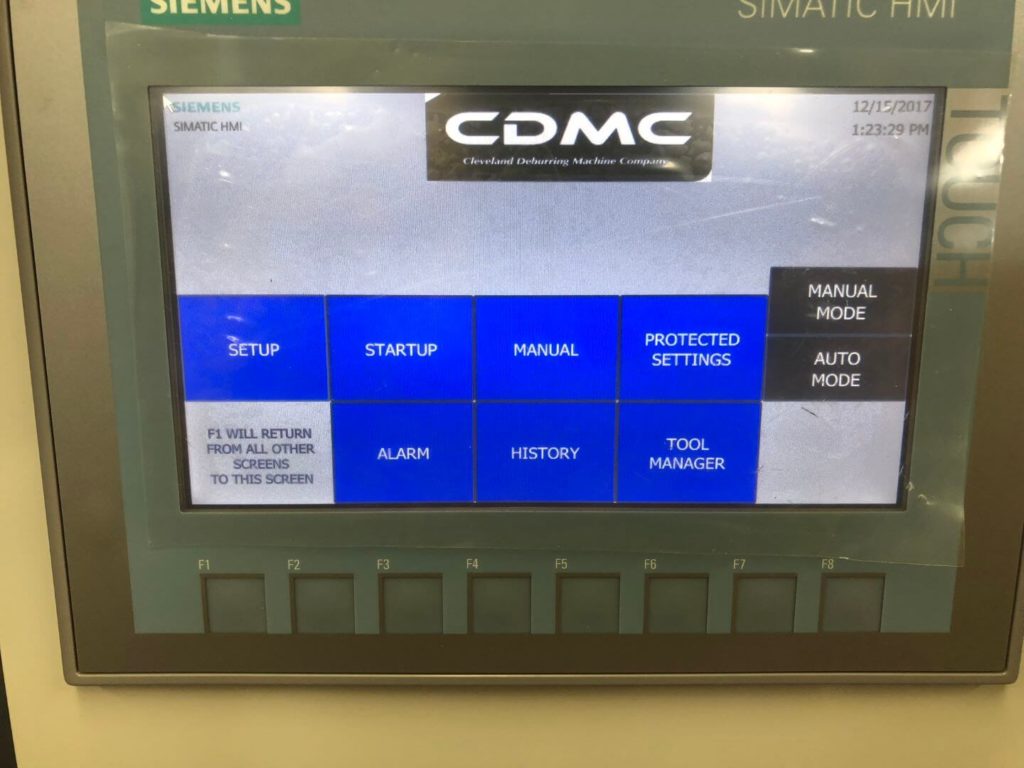

Marine Engine Component Deburring and Chamfering

JOB NO. 304

MARINE GEARS

Application

A top manufacturer of marine equipment required a deburring and chamfering to be cut into a family of gears. The family consisted of eight different gears, requiring multiple, quickly interchangeable work holdings. Customer requested part spindle that would move horizontally as to be loaded/unloaded by an external robot. Customer also requested a wash-down system for machine maintenance/cleanliness.

Solution

Processing

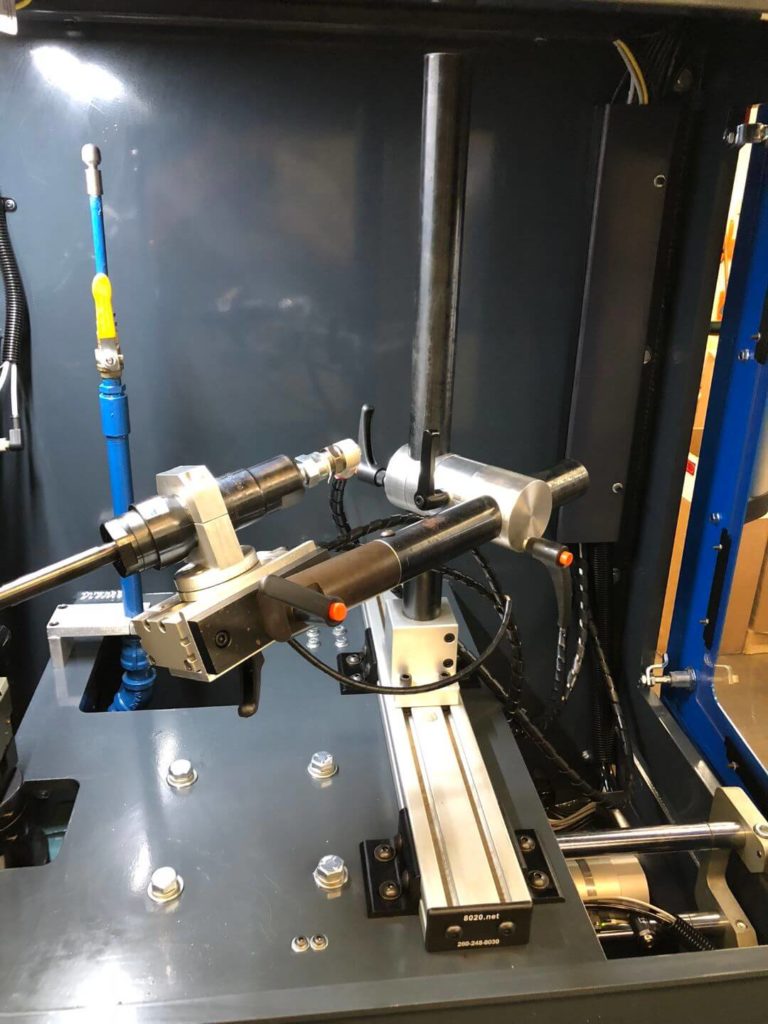

- A 20,000rpm air motor is used to drive a 3”-4” grinding wheel over the work surface.

- A pneumatically controlled rotary actuator is used to hold the air motor on center and allow it to follow the work surface contours lightly.

- 2 precision regulators are used to control cut and lift pressures. When the desired chamfer dimension is achieved, cut and lift parameters are kept/set to achieve consistent results from cycle to cycle.

- The cutting head assembly is mounted on a tubular vertical and horizontal arm assembly with adjustment clamps. This allows the cutting head to be adjusted for different parts.

Work Holding

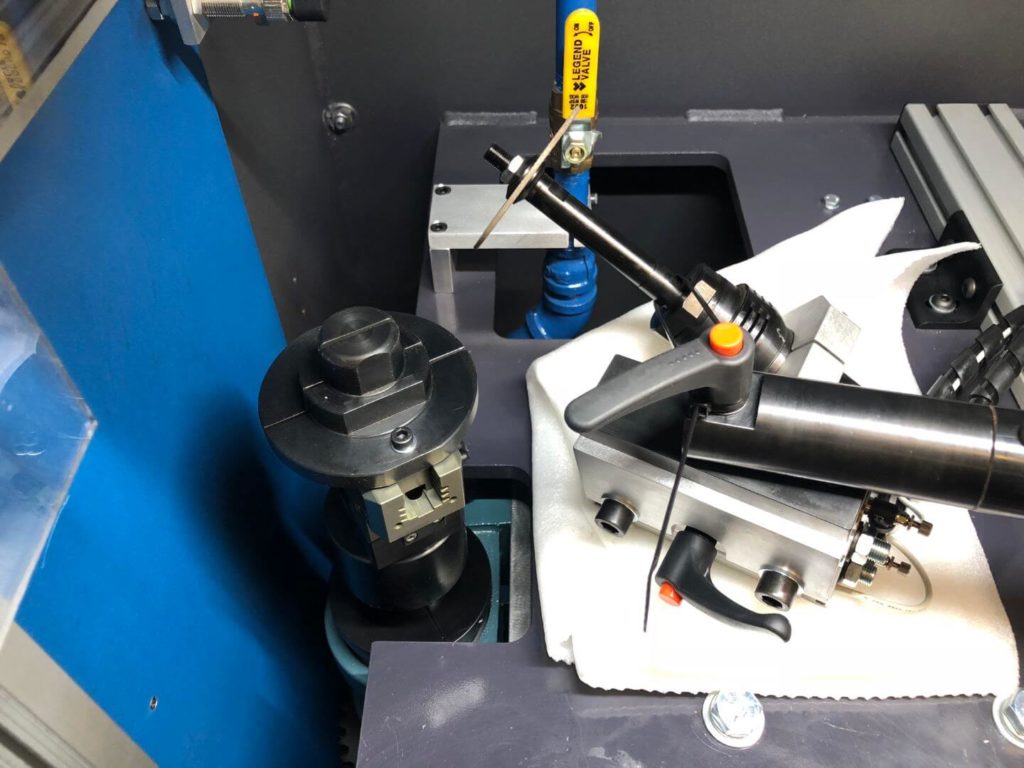

- To allow for quick-change work holding, a two-jaw pneumatic gripper is used with a set of hand-adjustable jaws.

- Split collets are designed for the full scope of parts and can be easily swapped onto the adjustable gripper jaws.

Customer Loading/Cleanliness Specs

- A linear slide is used to travel the part spindle to and from work/load position. In order to drive a mobile spindle, a stationary drive assembly is placed on a cushion with an output gear that will engage a gear on the spindle assembly when in the “work” position.

- A rotary spray nozzle is piped high above the work area in order to wash down the work area when activated within the work program.

Results