Master Tech

JOB NO. 143

CARBIDE INSERT EDGE PREP

Application

A manufacturer of carbide cutting inserts needed to perform edge preparation in a more timely manner (by adding a small radius to the sharp edge of a cutting tool, manufacturers can increase life and performance). The machine needed to be clean, low cost and have a small, mobile footprint.

Solution

Process

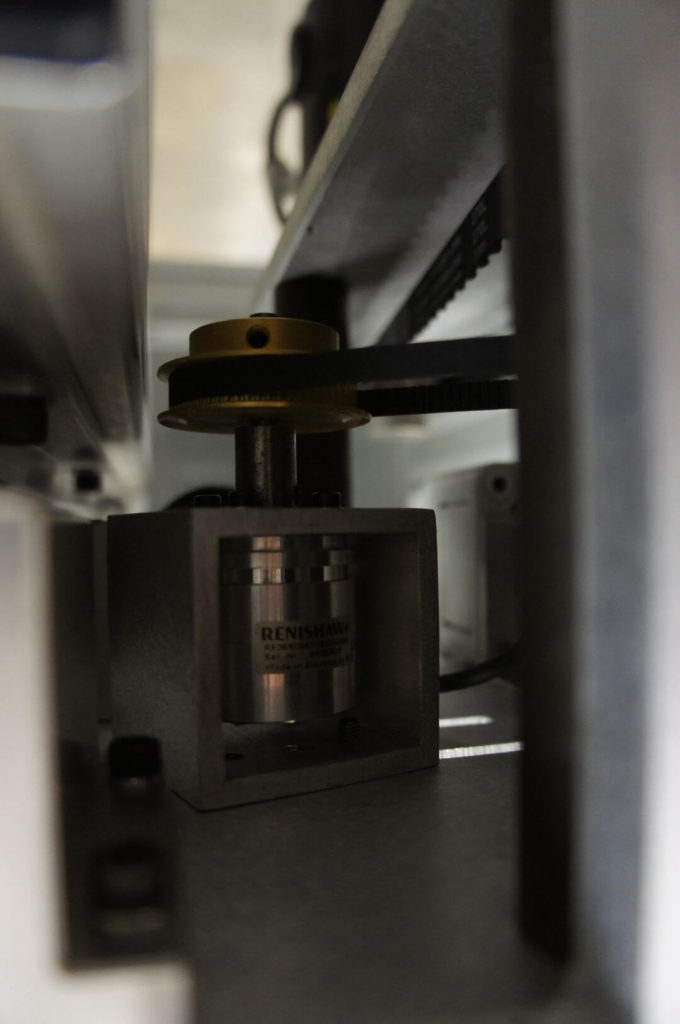

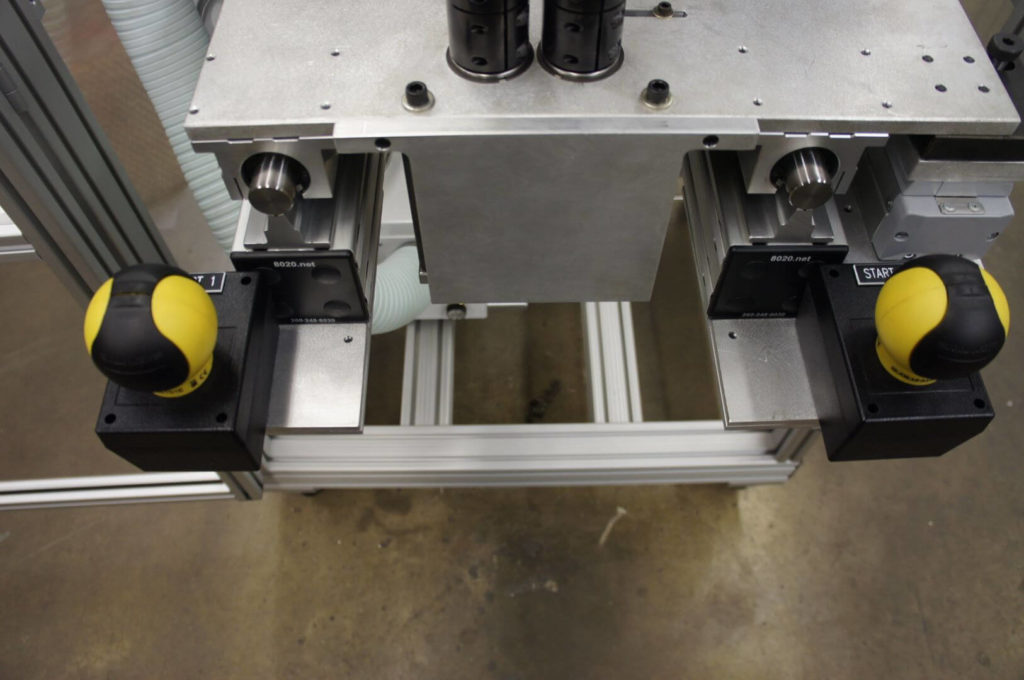

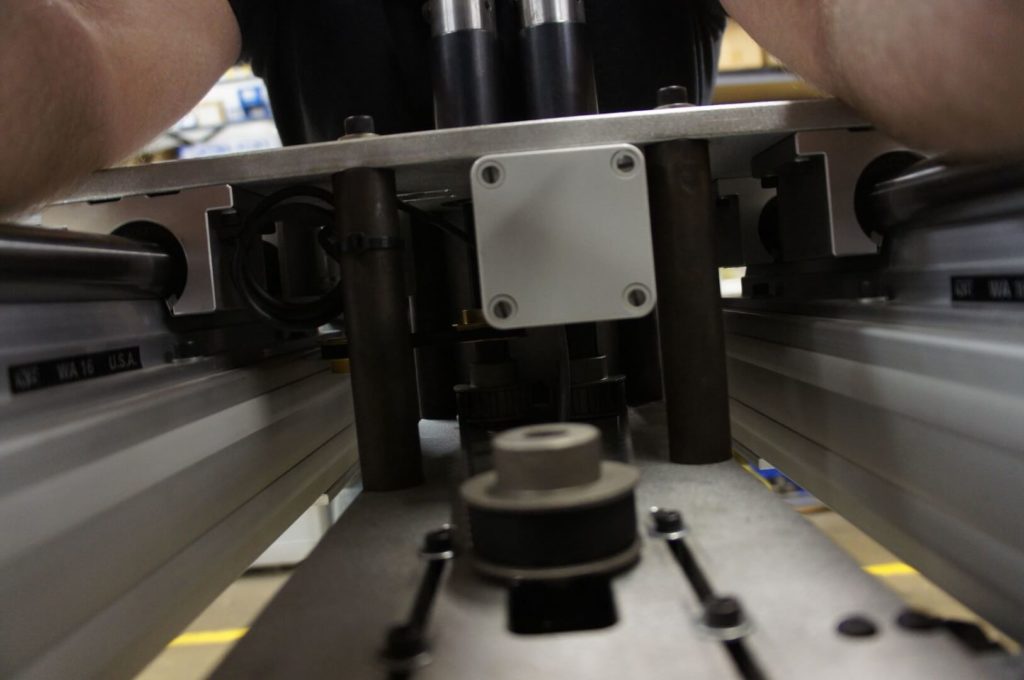

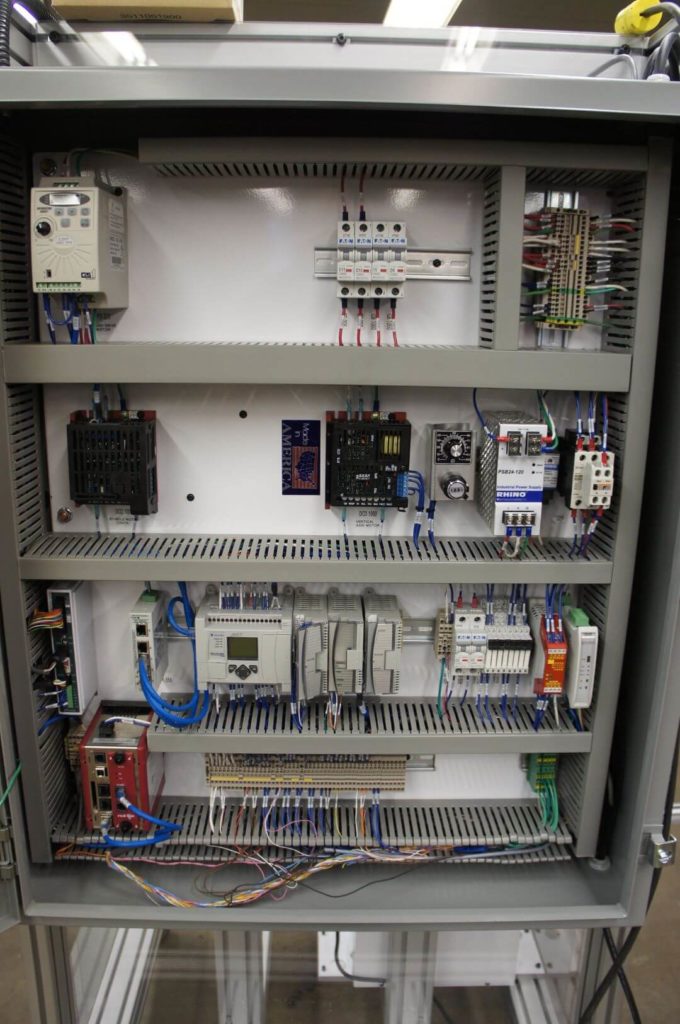

- Custom fixtures hold each insert to one of two drive spindles. Spindles are driven by a single electric drive motor via offset belt drive.

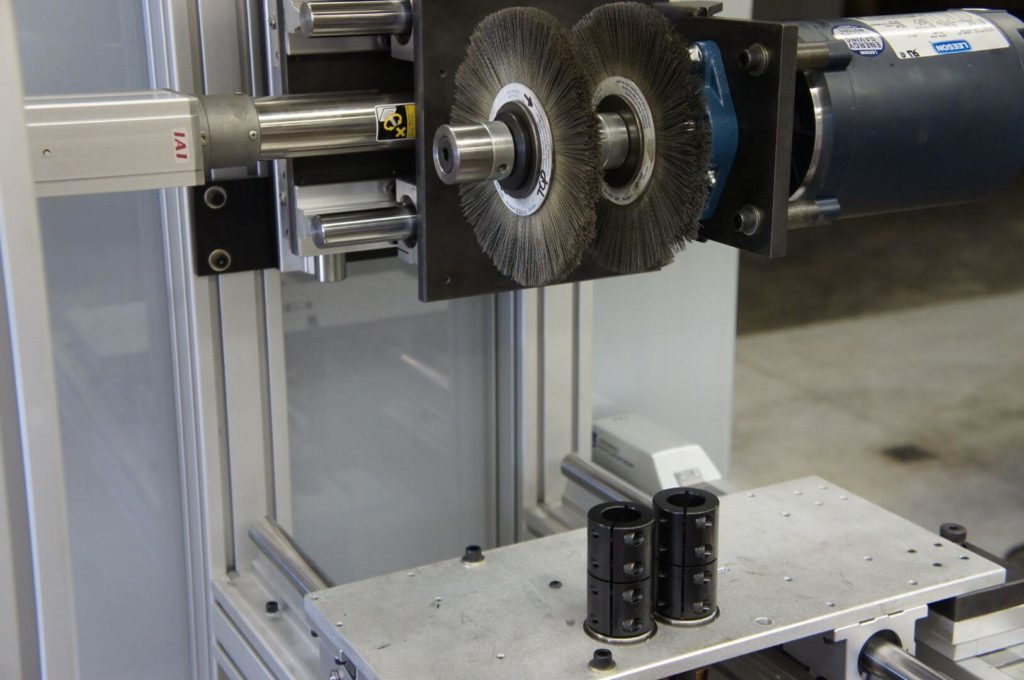

- A 2-axis motor slide sweeps across the tool inserts in a programmed motion. Nylon or diamond abrasive brushes are used.

- Horizontal and vertical axes are controlled by electronic linear actuators.

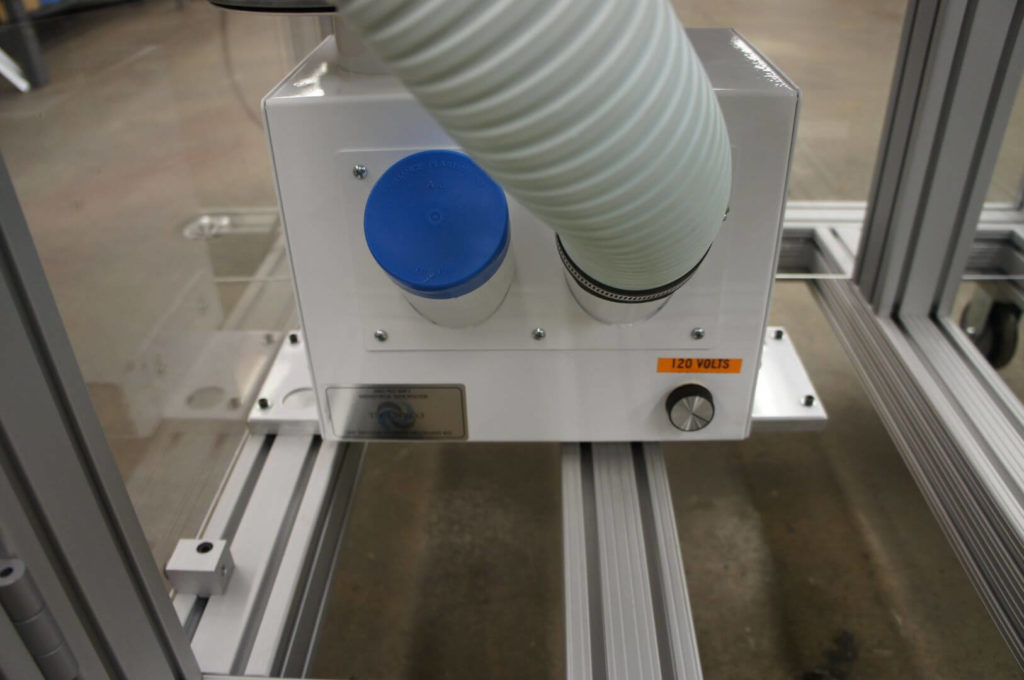

- During cycle, a small dust collection unit works to keep the work area free of debris.

Machine Base

- Base consists of pre-fabricated aluminum extrusion and is quick to assemble.

- Base is on wheels to allow for easy transport.