H & S Valve

JOB NO. 162

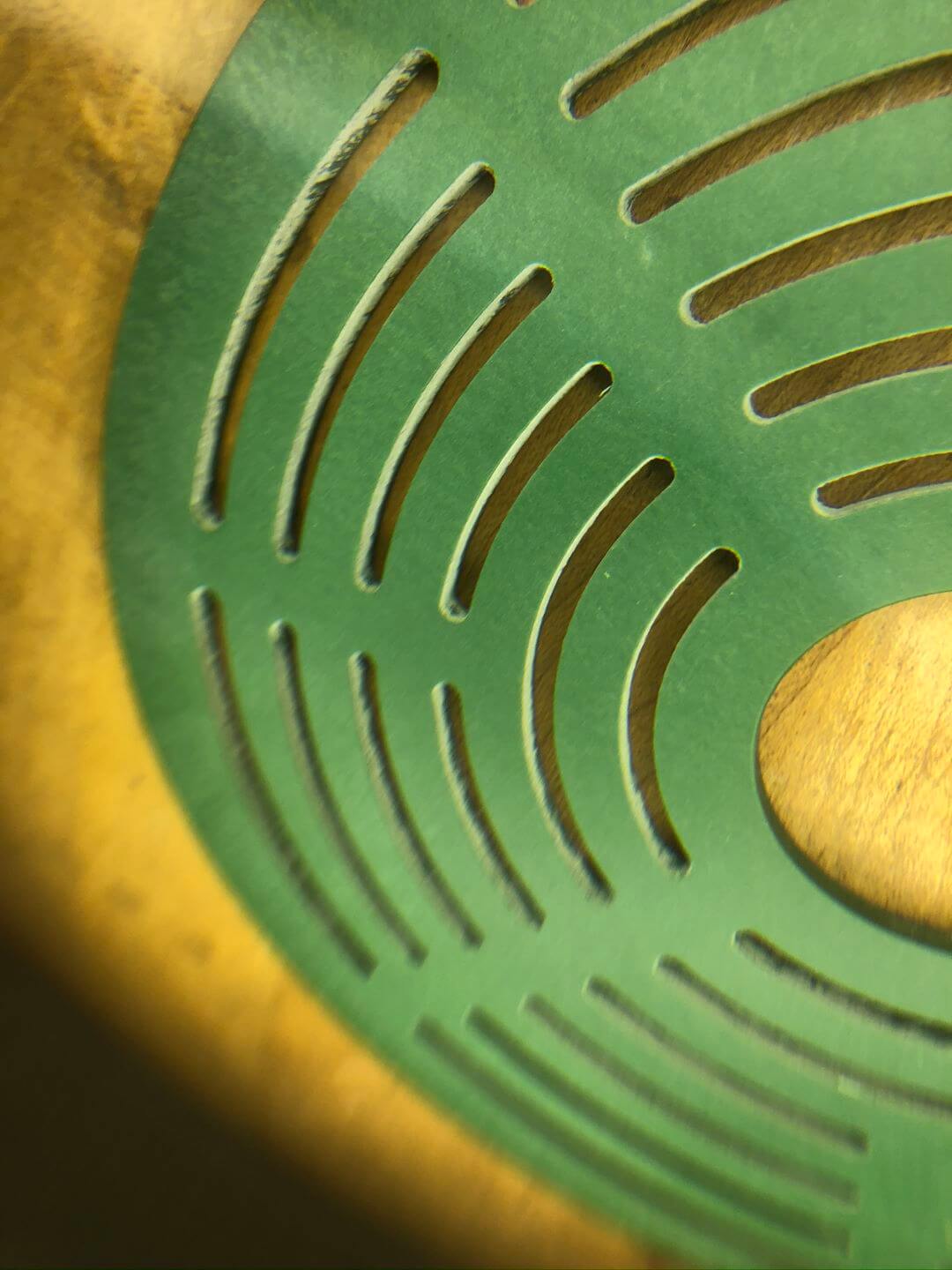

PHENOLIC COMPOSIT PLASTIC VALVE COVER SINGLE-SIDE DEBURRING

Application

A manufacturer of plastic valve covers needed a solution for mass processing/removal of burrs created by slot milling. A small, low-cost mobile machine was requested. Due to the nature of the material to be brushed, dust collection was a must-have.

Solution

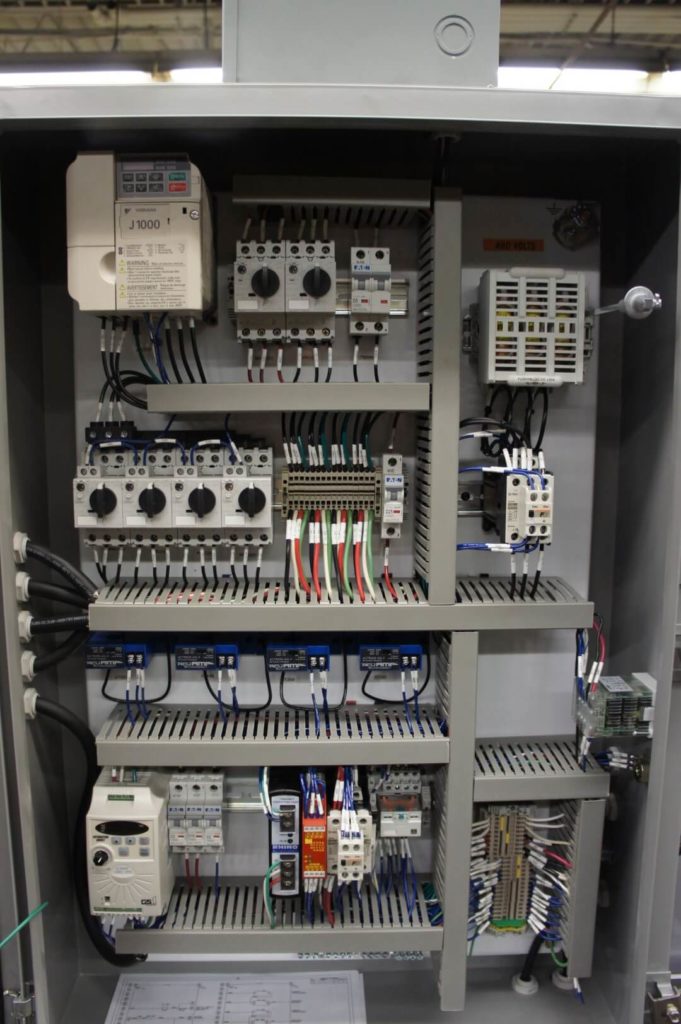

Machine Base

A low-cost aluminum extrusion base with polycarbonate safety glass panels is used. Machine casters are provided by the extrusion manufacturer and enable the base to be moved easily on the customer’s floor.

Processing

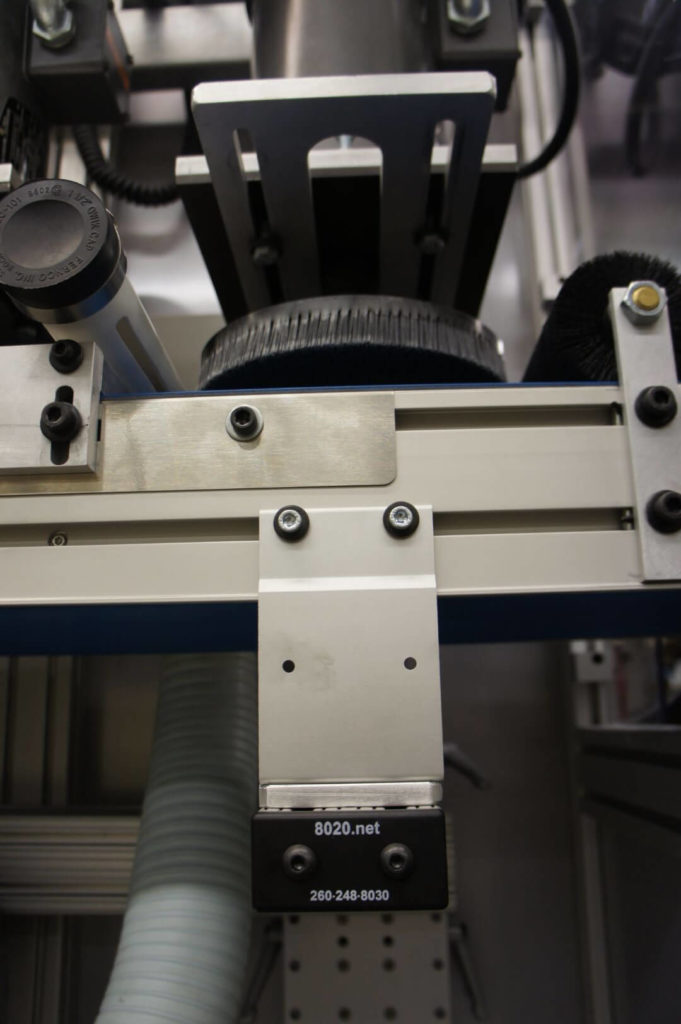

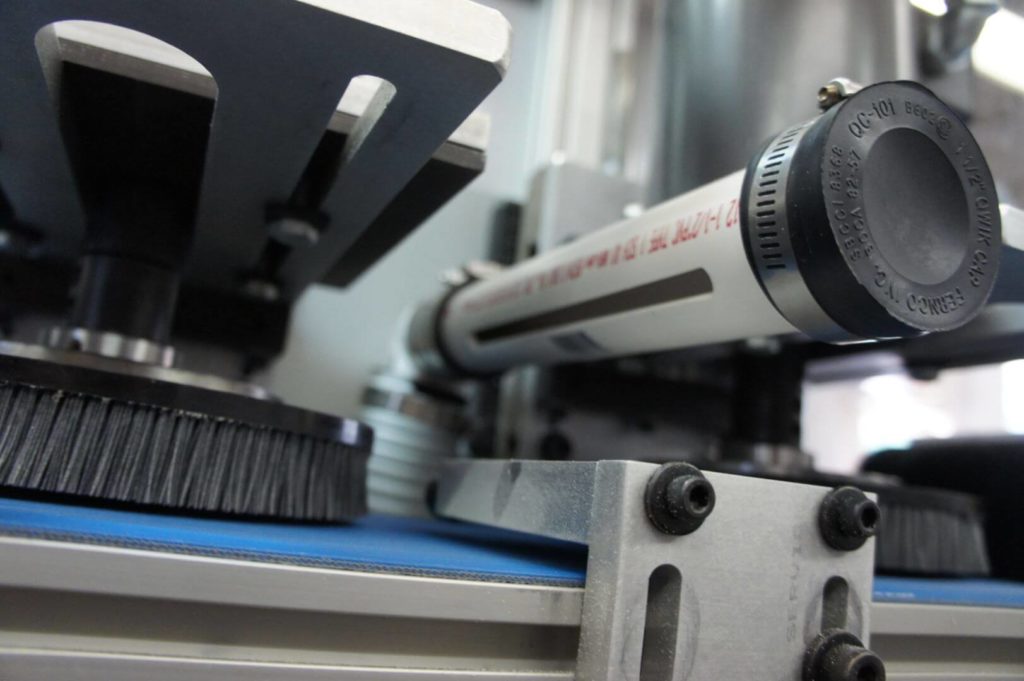

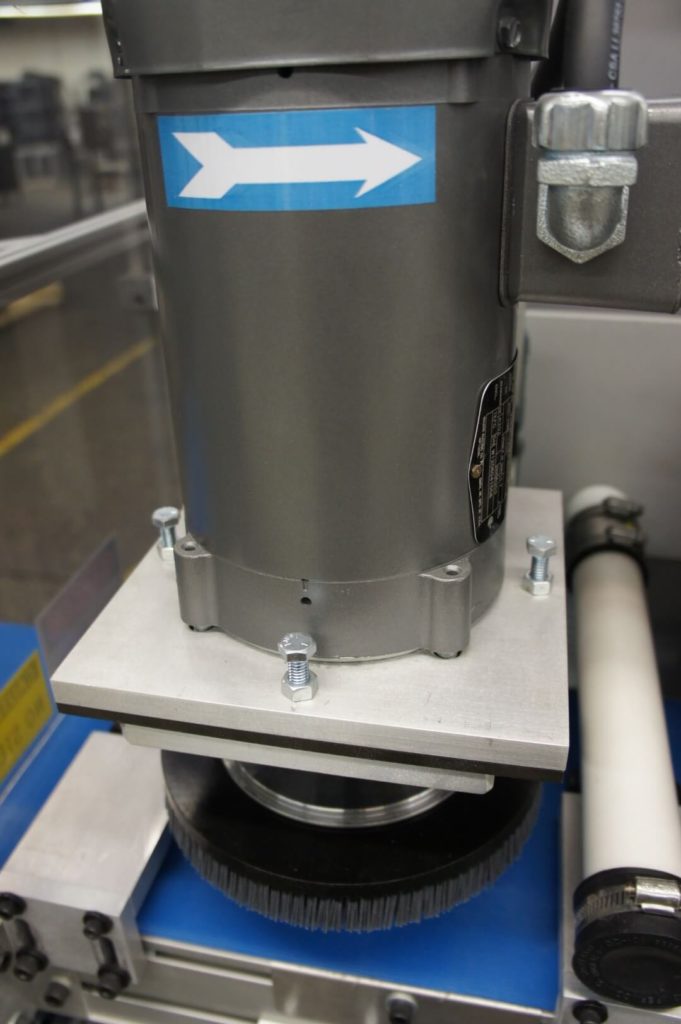

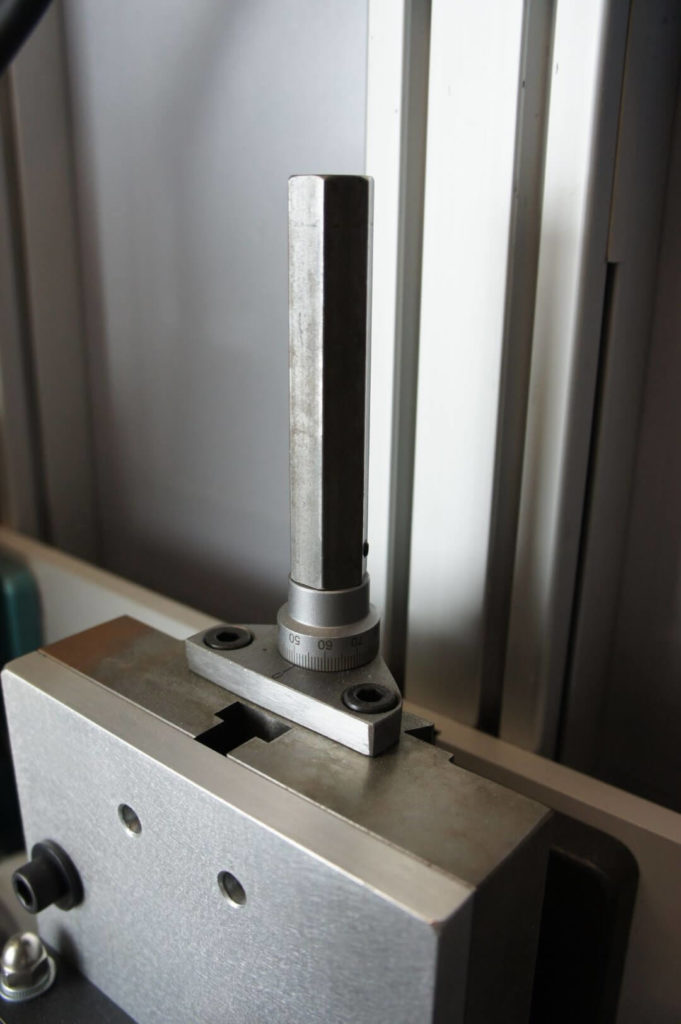

- Work pieces enter the machine with burrs facing up. A DORNER conveyor carries the work through a set of staggered nylon abrasive end brushes. The brushes are directly driven by medium frame D.C. motors mounted to vertical PALMGREN slide tables. Brush engagement is tool adjusted via hex heads at the top of each slide unit.

- As work pieces exit the machine deburred, a water tank uses pneumatic pressure to spray a mist of water onto the underside of the conveyor belt. The moisture is then distributed/used to clean the belt by a sponge located at the incoming conveyor end.

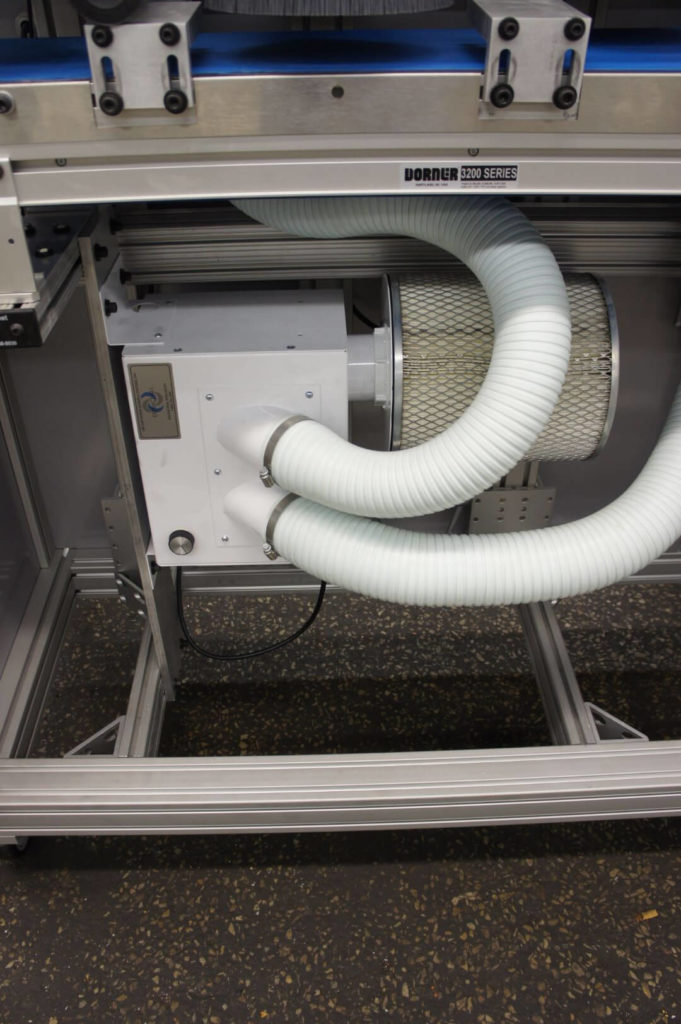

Dust Collection

- An EXTRACT-ALL dust collection unit is mounted beneath the work area. Dust collector ports are routed to custom pvc intake ducts located between brushes 1/2, 3/4.

Results