Clad Cookware

Application

A world-class cookware manufacturer needed a solution to deburr and surface prep blanks for coating. Blanks were large diameter flat metal and could not be gripped on the OD. A custom solution was needed in order to transition work pieces from load-work-unload. The customer required the large-scale operation to be enclosed in a safe room as well.

Solution

Processing

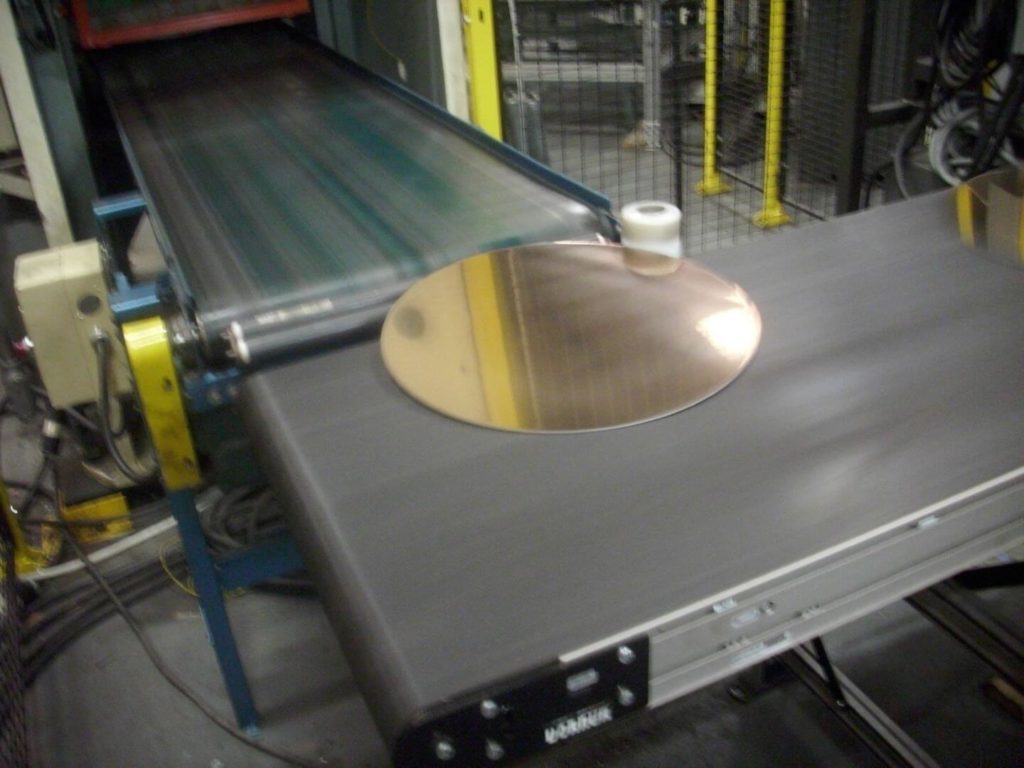

- Blanks are transported to the deburring cell via robot with vacuum pressure. They are dropped onto a load area where they are then transported to a work spindle by a 2-axis slide assembly (pick and place). A vacuum system will be used throughout the entire process to “clamp” and transport work pieces.

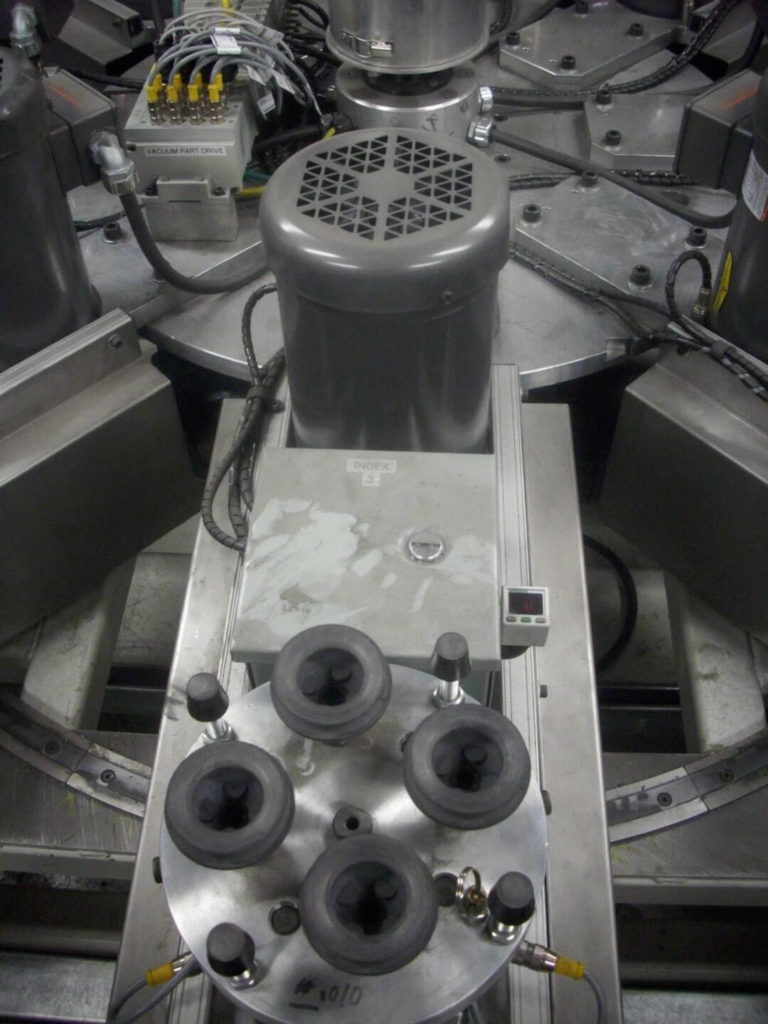

- Work spindles are installed to a large diameter dial plate assembly. The dial plate is rotated to each individual station by a CAMCO indexer. The six-station indexer is manufactured to stop/dwell at individual points and offers excellent locational repeatability. A vacuum distribution manifold is installed atop the dial plate in order for each part drive to receive sufficient holding pressure.

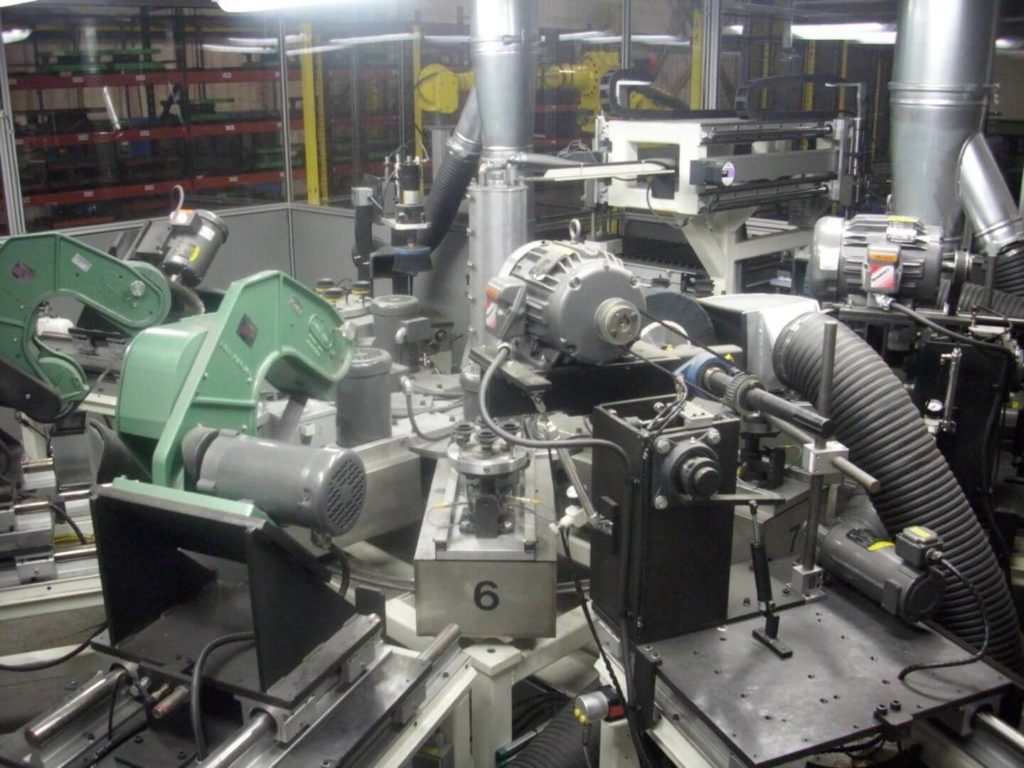

- From load to unload, the blanks will stop at a number of stations designed to sand the sharp edges away. These stations consist of a CDMC purchased BURR KING belt sanding unit installed to a linear rail assembly. Electronic linear actuators use Auto Amp Compensation to determine cut pressure.

- Once deburring is complete, blanks will travel to a number of stations designed to buff/polish the work surface, depending on the desired result. Similar to the sanding stations, buff stations are controlled via electronic actuator on a linear slide assembly.

Safety/On Site Requirements

- In order to satisfy safety requirements, an aluminum extrusion supplier was contact to aid in the design and installation of a safe enclosure. Pre-fabricated kits were used on site to build walls, windows and a ceiling to protect employees from this machine’s work area and byproducts. Any/all door interlocks and safety implementations were installed/provided by CDMC.