Case Study Spiral Bevel Gears

The Challenge

Our customer is a major manufacturer of heavy construction equipment. They needed a solution to the deburring of large spiral bevel gears and their mating pinions in short runs. Their parts ranged from 20 to 48 inches in diameter. The old deburring method relied on very experienced employees using hand grinders. While deburring quality was good, production needed to be ramped up and training someone to do a proper job was a lengthy process with no assurance that the employee would stay. Quality was hard to measure due to the wide variety of “acceptable” part parameters. This requirement called for a short-run deburring powerhouse with predictable, reliable output.

The Solution

The burr condition definitely called for some type of grinding wheel application. Our deburring engineers attached the grinder to a Fanuc robot which could be programmed with “recipes” for processing specific parts and is fully integrated with the machine. Once created and stored, each recipe is easily and quickly recalled. The gears are rotated on a large chuck for deburring.

The heaviest burrs existed at the heel of the spiral (the OD of the part) and were removed by a large flap wheel disc. This deburring process was followed by the robot grinder which applied a uniform dimensional chamfer on the heel profile. The toe area (part ID) had a smaller entry burr which was easily removed by the grinder, also applying a dimensional chamfer.

The Benefits

The very predictable and repeatable nature of this deburring process for spiral bevel gears yielded immediate gains in product quality, which allowed for smaller spare parts inventory and faster turnaround times. Flexible production schedules and last minute orders are now easily accommodated and deburring production can continue regardless of who calls in sick. Virtually all process variables have been eliminated, making results more quantifiable and outcome more consistent and predictable. The 3040-RF makes productive short-run deburring possible.

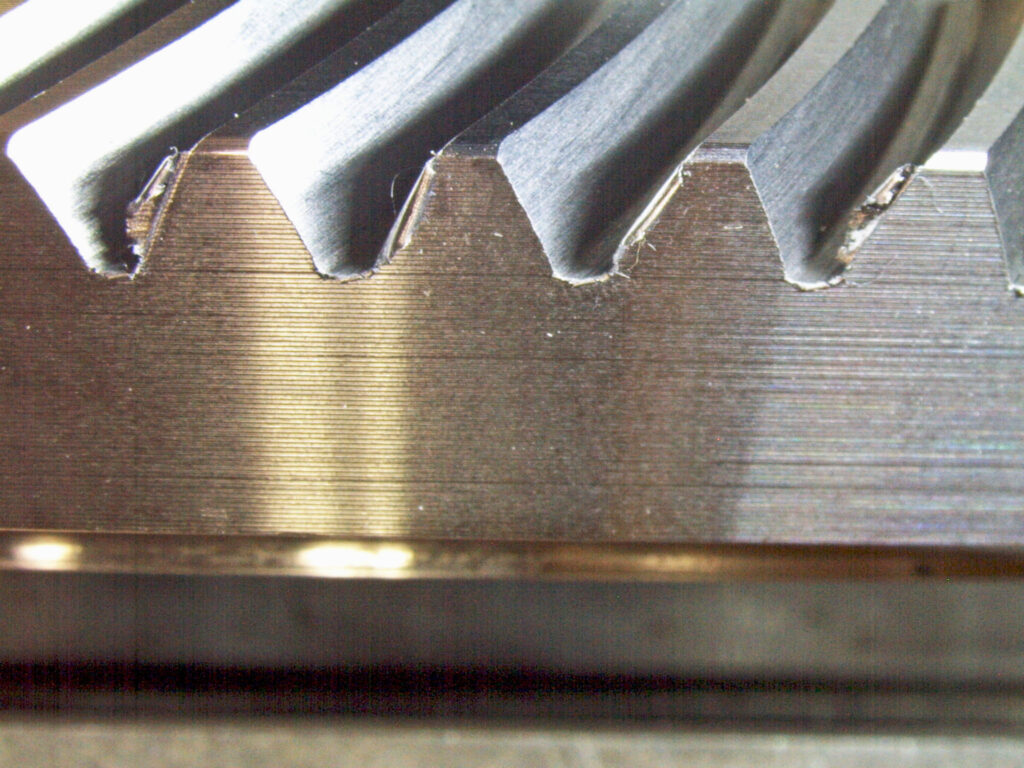

Before

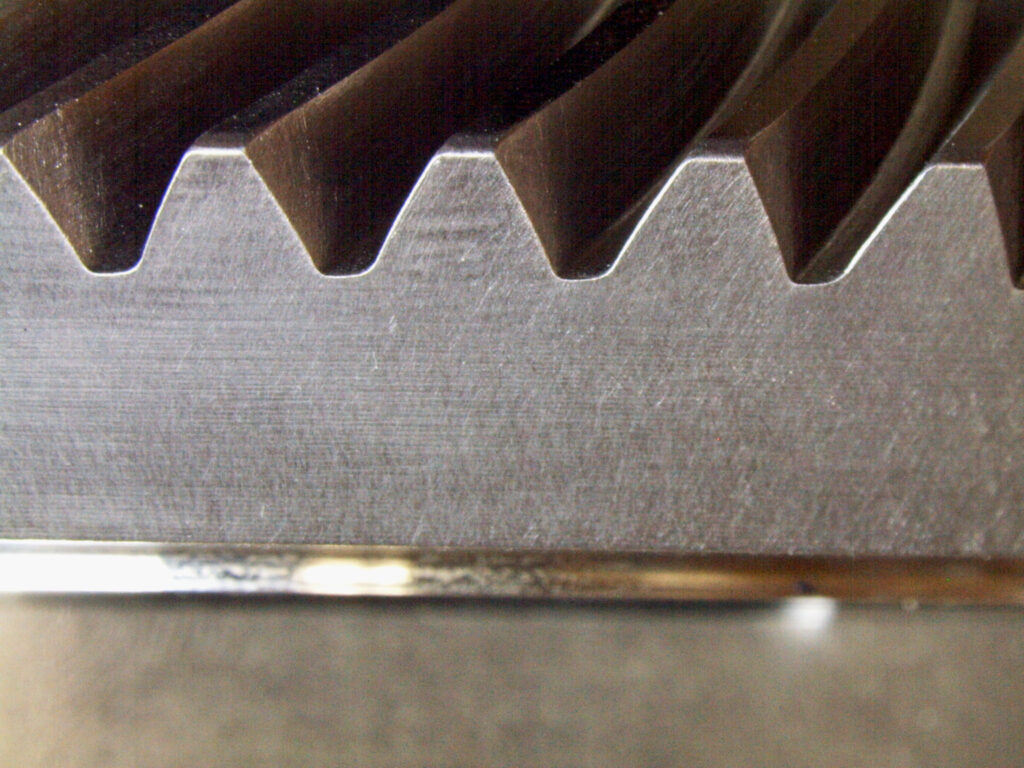

After